Soldering Fluxes

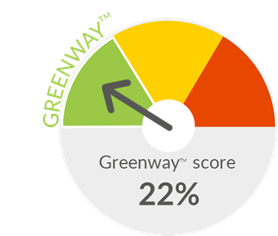

Best in class liquid solvent- or the more environmental friendly water based fluxes for wave, selective soldering and tinning. Our range of tacky fluxes, including resin based, no-clean, low-residue.

Select subsegment :

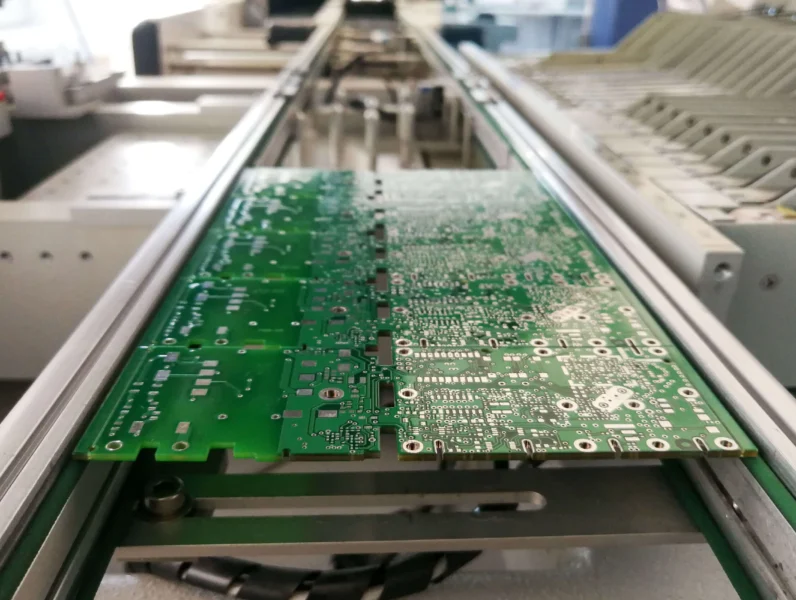

Wave Soldering flux

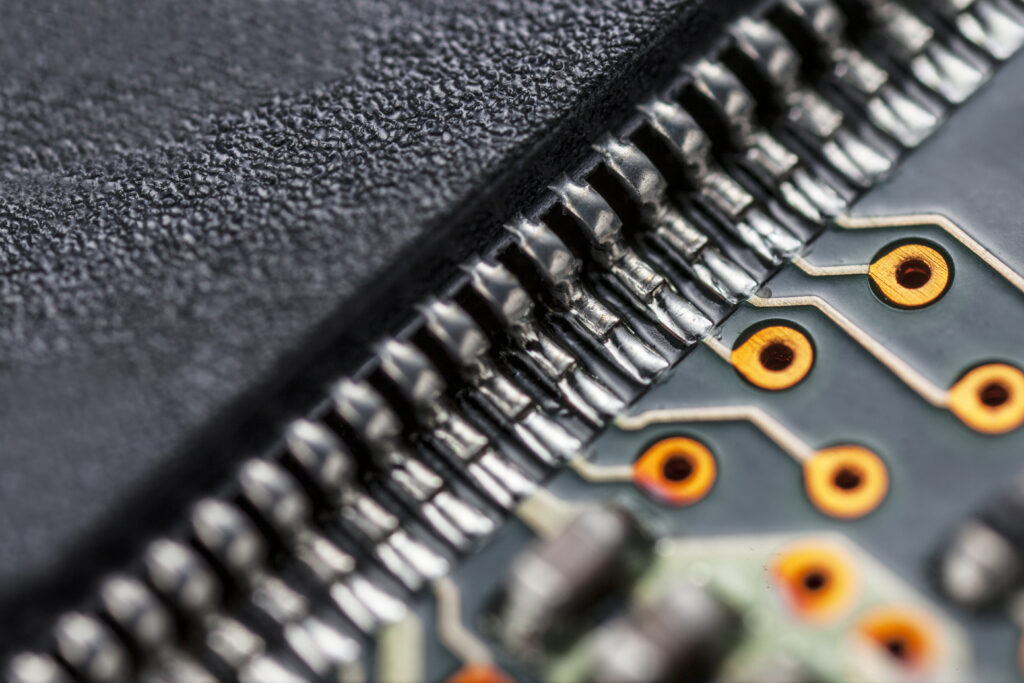

Wave soldering flux is essential for cleaning metal surfaces, preventing oxidation, reducing surface tension, and ensuring proper solder flow to create strong, reliable solder joints and minimize defects during the wave soldering process.

THT-components, connectors, switches and power semiconductors are commonly soldered through wave soldering processes. Our ECOFREC™ fluxes ensure great wetting properties, optimize on solder flow and achieve high-reliability solder joints.

Adapted solutions are available for different soldering needs including alcohol or the more environmental friendly water based (100% no VOC) formulations.

Read moreSelective Soldering flux

Selective soldering flux plays a significant role in the electronics manufacturing process by facilitating the flow of solder, preventing oxidation, and minimizing defects, which ultimately enhances the reliability and durability of electronic components and assemblies.

Connectors, switches and power semiconductors are usually soldered on PCBA’s through selective soldering processes. ECOFREC™ flux innovations ensure great wetting properties, optimize on solder flow and achieve high-reliability solder joints.

Adapted solutions are available for different soldering needs including alcohol or the more environmental friendly water based (100% no VOC) formulations.

Read moreTacky Flux

Tacky flux is essential in soldering processes as it helps to clean and prepare metal surfaces by removing oxides, ensuring better adhesion of the solder, preventing contamination, and improving the overall reliability and strength of electrical connections.

How is AMTECH Tacky Flux Manufactured?

Video Player

Tacky fluxes are mainly used for rework on PCBA, BGA repair, BGA-reballing, QFP rework or Package-on-Package soldering. Application can be made by dispensing, squeegee or doctor blade.

ECOFREC™ tacky fluxes show excellent wetting properties together with optimized rheology and high product stability.

Read moreTinning Flux

Tinning flux is important in soldering because it cleans and prepares metal surfaces by removing oxidation, ensuring better adhesion of solder and preventing weak joints, which improves the reliability and longevity of electronic connections.

For cable assembly, good wetting properties and spreading abilities of fluxes used is required to achieve uniformly tinning results.

ECOFREC™ flux solutions are widly used to achieve great results.

Read moreTechnical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provides FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.