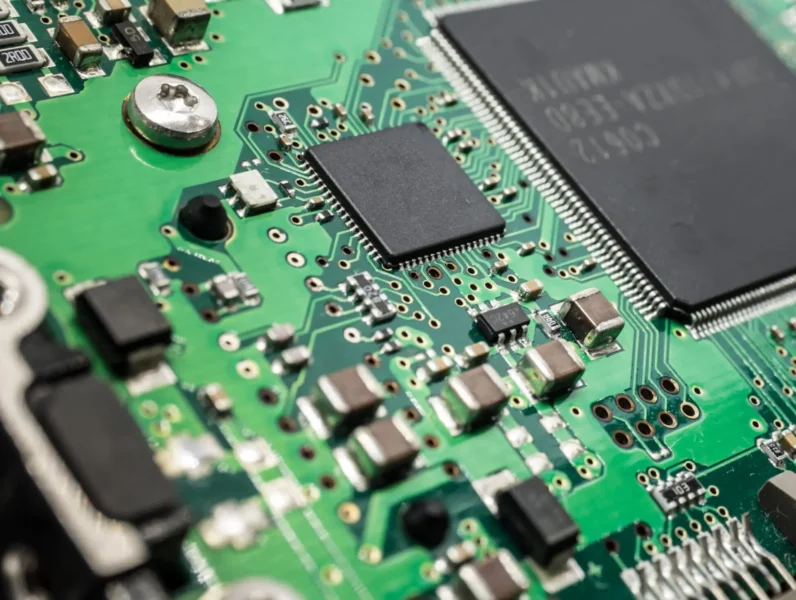

SMT Solder Pastes

Our dedicated offer of solder pastes for the SMT process, combining different alloys, powder size and flux media for printing, dispensing and assemblies.

Select subsegment :

High Reliability

Solder Paste

As some electronics are used for people’s safety or expected to operate under extreme conditions for many years, standard solder pastes may technically not be up to the task resulting in premature failure of the electronics.

Chemical Reliability

Most no-clean flux residues after reflow are chemically inert to only some extend and cleaning or in other words, defluxing is an option still not always desired.

INVENTEC targeted from the early days high reliability applications. We were one of the first companies providing halogen-free formulations and to use BONO test to confirm the reliability of our solder products. This allowed us to fine-tune over those years well balanced solder solutions with highly inert flux residues.

Mechanical Reliability

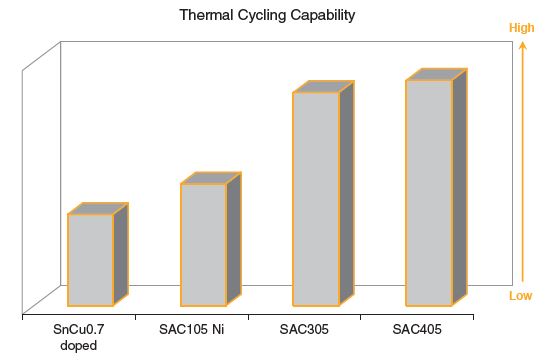

The strength of the solder joint is defined by the mechanical reliability properties of the alloy. Some electronic assemblies have to deal with fast and extreme temperature changes, high temperatures, vibrations or need some resistance to drops. Choosing the right alloys for a particular need is key.

In the past, leaded alloys where the solution to electronic assemblies exposed to extreme temperature changes but due to environmental concerns they have been prohibited to use (with a few exceptions). Lead free alternatives, like SAC405, SAC378 and other variations have been introduced over the years. Inventec’s R&D team is constantly looking for improvements in this field.

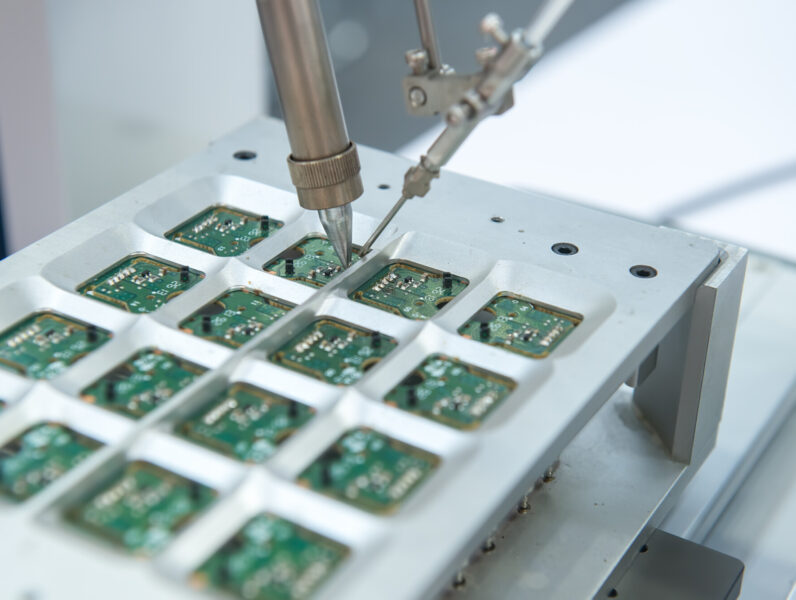

Read moreJet Printing & Dispensing Solder Paste

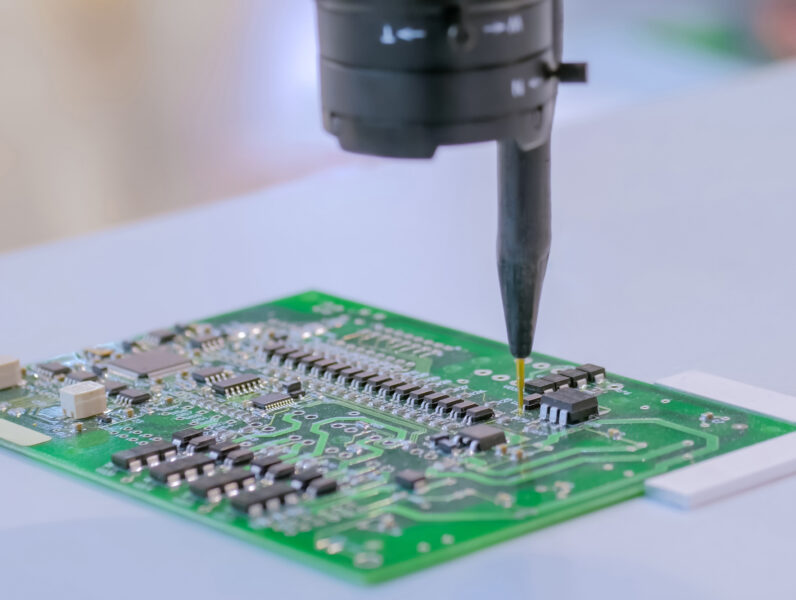

Jet printing and dispensing solder paste play a crucial role in SMT (Surface Mount Technology) by ensuring precise, efficient, and consistent application of solder paste, which is essential for achieving reliable and high-quality solder joints in electronic assemblies.

Jet Printing Solder Paste

Our jet printing solder pastes are especially designed to work on jet printing equipment and to guarantee continuous and consistent deposits of solder paste.

Although the flux is chemical inert, it is easy to clean with water or solvent based processes. It is optimized to be used on Mycronic, Vermes, Essemtec and Musashi jet printing equipment.

Dispensing Solder Paste

Dispensing solder paste is a very flexible manufacturing process, allowing solder pastes to be put into cavities and on top of mounted components. Furthermore different dot sizes can be achieved within a single process setup.

Our dedicated jet printing & dispensing solder pastes offer optimized flow properties and viscosity ranges to achieve best results using these manufacturing processes.

Read moreLow & No Silver

Solder Paste

Low and no silver solder paste is essential in SMT applications as it helps reduce material costs, enhances solder joint reliability, and minimizes the risk of corrosion while maintaining high-quality performance.

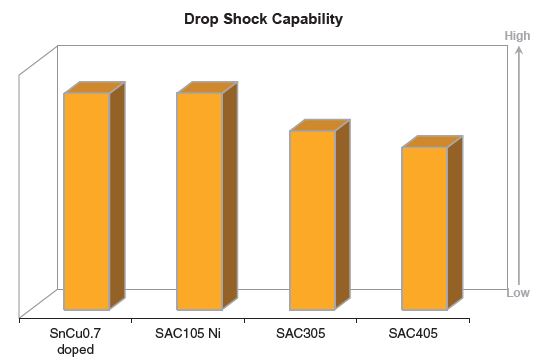

Low and No silver solder solutions are often selected to reduce cost but a reduced silver content can also improves substantially the drop shock performance of an electronic assembly.

Typical applications where drop shock is important are consumer electronics and more particular, handheld devices. In recent years however, we see these alloys also used in industries as Automotive & Energy.

The alloy characteristics in combination with the high performance chemistry of the ECOREL™ range provides very good wetting and a robust assembly process for high volume electronics.

Read moreLow Temperature

Solder Paste

Low temperature solder paste is important in SMT (Surface Mount Technology) applications as it enables reliable soldering of temperature-sensitive components while reducing the risk of thermal damage.

Breakthrough technologies have enabled a wider use of low temperature solder (LTS) processes and in recent years they are used increasingly as an alternative to SAC305 assemblies.

The benefits are not limited to soldering temperature sensitive components as also board to board warpage is significantly reduced, it opens up the possibility for a single pass process and provides more design freedom.

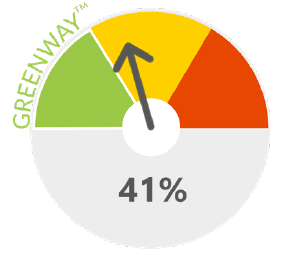

From an environmental & cost perspective, LTC reduces energy use substantially and hence CO2 emissions.

Read moreLow Voiding

Solder Paste

Low voiding solder paste plays a key role in SMT (Surface Mount Technology) by minimizing air pockets during reflow, ensuring reliable electrical connections and enhancing the long-term performance and durability of electronic assemblies.

Voiding in solder joints is a concern in high reliability electronics like automotive, power electronics, LED lighting, etc, as electrical conductivity and thermal dissipation performance are lowered if the percentage and the size of voids are too high. Also voids could reduce the mechanical strength of the joint.

Large area components such as bottom termination components (BTC) and components with bottom thermal plane (DPAK) are particularly critical. So the reduction of voids level and voids size is very important to achieve the expected reliability in such assemblies.

Many factors are responsible of voiding, including the solder paste as voids being partly caused by flux outgassing which remain entrapped in the solder joint. In order to reduce the voids level in an electronic assembly, using a dedicated low voids solder paste is recommended.

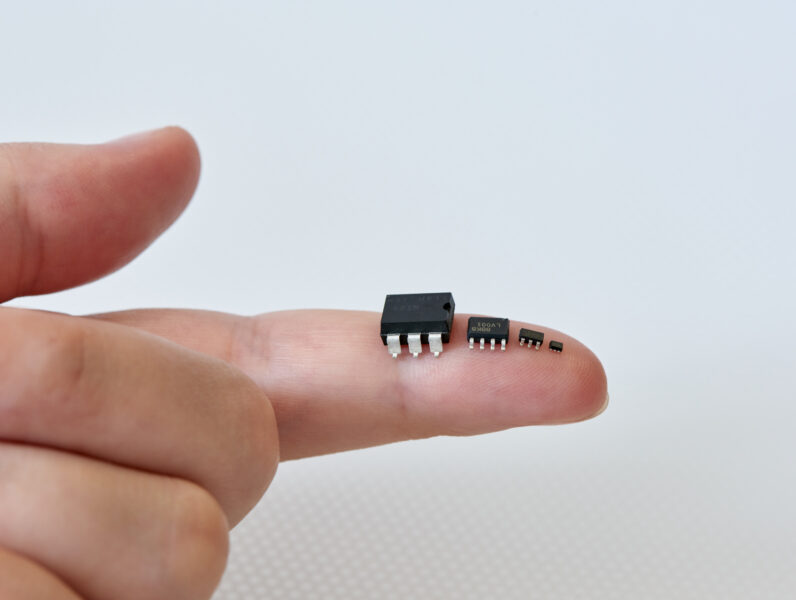

Read moreMiniaturization

Solder Paste Solutions

Miniaturized solder paste solutions are vital in SMT, enabling precise application for smaller components and ensuring reliable, high-quality connections in compact, high-density electronic devices.

The trend toward miniaturization in the field of electronics manufacturing continues with smaller components being placed in even more compact spaces. As a result, the demand for solder pastes containing smaller metal particles is increasing.

All of our recent solder paste products are standardized to powder size Type 4, but we also offer solutions in T5 and T6 to overcome challenges related to ultra-fine pitch electronics manufacturing.

Since the demand for solder pastes with ultra-fine powder size is still relatively low and highly specific, we are further developing products based on the needs and requests of our customers. Please contact us for more details on the availability of powder size related to a specific alloy and in combination with our ECOREL™ flux medium. We are flexible and can develop products according to your specific requirements.

Read moreRobust Assembly

Solder Paste

High Volume PCB Assembly Solder Paste plays a critical role in ensuring consistent and reliable solder joints during high-speed surface mount technology (SMT) processes, enabling efficient, precise, and high-quality mass production of electronic devices.

Printing and soldering results can differ through impacts caused by equipment & equipment settings, stencil qualities, reflow methods and much more.

Our robust assembly solder paste range offers paste solutions optimized for a larger process window, reproducible reflow results and well balanced overall performance.

Read moreWater-Soluble

Solder Paste

Water-soluble solder paste is necessary in SMT (Surface Mount Technology) applications as it ensures efficient soldering with minimal residue, allowing for easier post-reflow cleaning and improved overall board reliability.

ECOREL™ water-soluble solder pastes combine optimized wetting properties together with great printing performance.

Remaining flux residues can mostly be cleaned using DI-water, but when better cleaning results are required, we can offer efficient defluxing solutions perfectly matched with our flux formulation and showing great material compatibility.

Besides, SMT-stencils can on average be easily cleaned with DI-water or just with a small amount of cleaning detergent.

Read moreTechnical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.