Rework & Repair Solutions

Solder pastes, liquid and tacky fluxes, flux cleaners in an optimized packaging for re-work & repair.

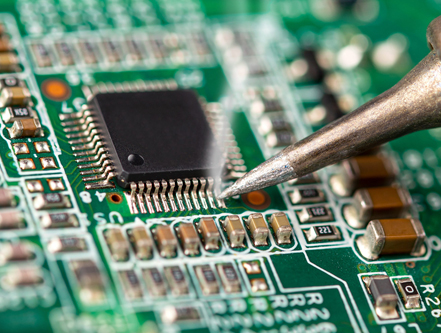

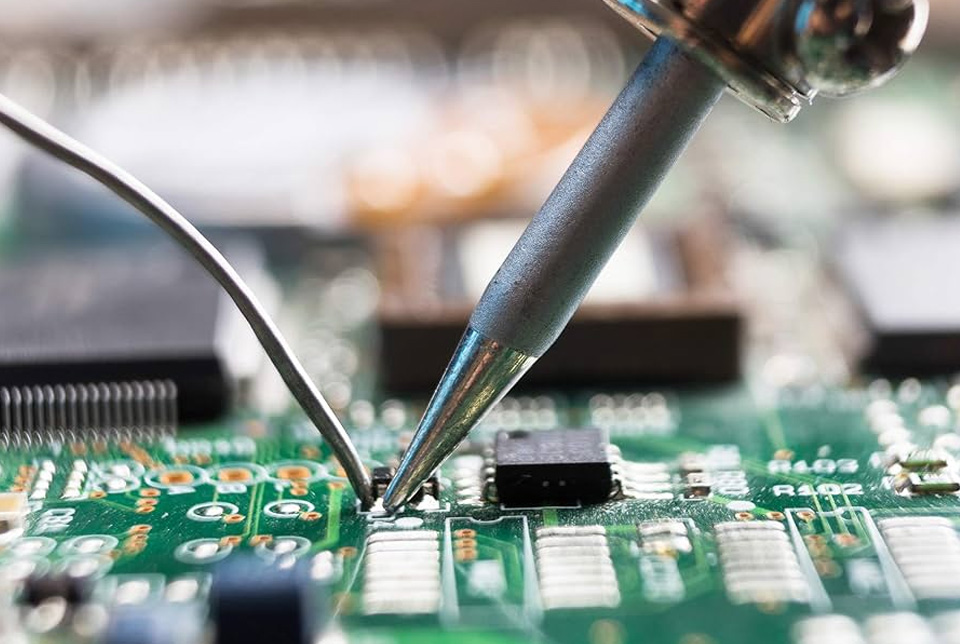

Solder Paste Repair and Flux Technologies for Every Solder Rework Challenge

Precision-engineered for restoring quality and performance, solder rework and repair solutions combine advanced solder flux and solder paste technologies to ensure reliable connections, clean rework, and extended product life in even the most demanding electronic assemblies.

Select subsegment :

Solder flux repair solutions

Solder flux repair solutions are essential in modern soldering, as they clean and prepare surfaces for optimal adhesion—enhancing solder flow and bonding. Trusted by industry professionals, INVENTEC provides high-performance solder flux repair solutions that ensure strong, reliable connections in even the most demanding rework and repair applications.

When it comes to precision electronics repair, using the right solder flux repair solutions is essential for achieving reliable, long-lasting solder repair results—especially during complex rework soldering operations…

Learn more

Solder paste repair solutions

Solder paste repair solutions from INVENTEC are essential in advanced soldering applications, as they enable precise and efficient remediation of defective solder joints, thereby restoring full electrical functionality and operational reliability without necessitating complete circuit board replacement.

Effective solder paste repair solutions are essential for precise and reliable solder repair and rework soldering of complex electronic components like BGAs and QFNs…

Learn more

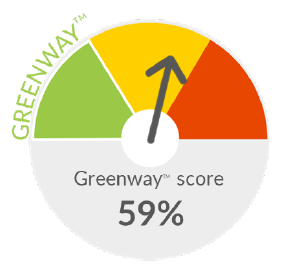

AMTECH™ Solder Solutions

INVENTEC USA, offering a comprehensive range of AMTECH solder pastes, solder powders, solder fluxes, and process support products for high-reliability electronic applications, has filed a lawsuit after a terminated distributor misappropriated its trademarks, trade names, and proprietary product naming system, unlawfully duplicating over 50 product names.

As a trusted provider of advanced soldering materials for the electronic assembly market, the company is taking firm action to protect its AMTECH brand and ensure the integrity of its genuine repair solutions, including solder paste, solder flux, and other critical products used in solder repair and rework soldering…

Discover our AMTECH™ Solutions

Read more

Discover Our No-Clean High Viscosity Tacky Flux for Rework and Repair Applications!

ECOFREC TF49

- Halogen free tacky flux

- Flip Chip & Rework soldering

- Low residue properties

- Lead-free and leaded applications

Industrial Soldering Solutions – FAQ Rework & Repair Solutions

What are Rework & Repair Solutions in industrial soldering?

Rework & Repair Solutions are specialized products designed to fix, replace or restore defective solder joints without compromising the integrity of the electronic assembly. They include solder pastes, liquid fluxes, tacky fluxes and flux cleaners tailored for precision rework.

Why are rework and repair critical in electronics manufacturing?

Rework and repair processes allow manufacturers to recover defective assemblies, reduce waste, save costs and maintain high production yield and reliability.

What products are typically used for soldering rework & repair?

The most common products include rework solder pastes, liquid fluxes, tacky fluxes, and flux cleaners. These enable precise solder joint correction and easy residue removal.

How does INVENTEC support rework and repair applications?

INVENTEC provides solder pastes, liquid fluxes, tacky fluxes and flux cleaners in optimized packaging designed for rework and repair processes, ensuring ease of use and process reliability.

What is the role of flux in rework and repair operations?

Flux is critical to remove oxides, promote wetting and improve solderability during rework. Tacky and liquid fluxes are used to stabilize soldering results while minimizing residues.

Why is packaging important for rework products?

Optimized packaging such as syringes, pens, and small-volume containers ensures easy application, precise dosing and reduced waste in rework and repair environments.

What advantages do INVENTEC flux cleaners provide for rework?

INVENTEC flux cleaners are formulated to remove residues efficiently, reduce contamination risks, and maintain long-term reliability of reworked assemblies.

How can rework solder pastes improve assembly quality?

Rework solder pastes are designed for low-voiding, excellent printability, and controlled reflow, which help restore solder joints to production-grade quality.

What are the key challenges in rework & repair processes?

Challenges include precise heat management, void control, residue removal, and maintaining component integrity. Proper product selection and optimized flux cleaners help overcome these issues.

How can manufacturers optimize rework & repair with INVENTEC solutions?

By using INVENTEC’s tailored solder pastes, fluxes and cleaners, manufacturers can improve efficiency, reduce scrap and extend product lifetime while ensuring compliance with RoHS and reliability standards.

Rework & Repair Solutions: Solder Flux and Solder Paste Repair Guide

Rework and repair solutions are essential in modern electronics manufacturing to correct assembly defects, improve yield, and extend product life. By using advanced solder fluxes and solder paste repair techniques, technicians can restore reliable electrical connections without compromising component integrity.

These solutions involve precise reflow processes, localized heating, and controlled flux application to fix issues such as tombstoning,

Benefits & Applications

Key BenefitsRework & repair solutions including solder paste repair solutions and solder flux repair solutions ensure precise and reliable component replacement or circuit board corrections. Optimized packaging facilitates process efficiency, minimizes material waste, and enhances repair success rates in demanding production environments.

Technical AspectsSolder paste repair solutions and liquid or tacky flux repair solutions are formulated for precise viscosity, controlled wetting, and compatibility with automated or manual rework stations. Specialized flux cleaners remove residues effectively without damaging substrates or components, ensuring reliable and repeatable repair operations.

ApplicationsRework & repair solutions are widely applied in the automotive, aerospace & defense, and medical industries to fix PCB defects, replace malfunctioning components, and ensure product reliability. These solutions support high-yield production, reduce downtime, and allow manufacturers to comply with strict quality standards.

Rework & Repair in Automotive Electronics

In automotive electronics, rework and repair solutions are used for power modules, ECUs, and sensor assemblies. High-quality solder fluxes and controlled solder paste repair ensure safe and reliable electrical connections in demanding automotive conditions.

Rework & Repair in Aerospace & Defense

For aerospace electronics and

Rework & Repair in Medical Devices

In medical devices, solder flux and paste repair solutions allow precise component rework on imaging, diagnostic, and monitoring equipment. This guarantees reliable electrical connections and long-term device performance essential for patient safety.

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free of Charge Cleaning Trials

Conduct and/or participate in free-of-charge cleaning trials in our Technical Centers with multiple machine types and a comprehensive technical report detailing all test results, process recommendations and critical process operating parameters will be provided.