Dielectric direct cooling fluids

What are direct liquid cooling fluids?

What are direct liquid cooling fluids?

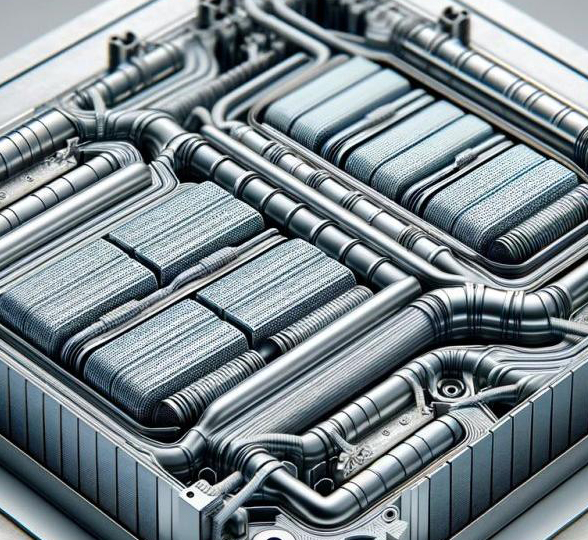

Direct liquid cooling fluids are used in cold plate and cold tube systems to efficiently remove heat from electronic components. In a cold plate system, the fluid flows through a flat plate attached to the component, transferring heat directly from the component to the liquid. In a cold tube system, the fluid circulates through tubes surrounding the components, absorbing heat as it passes.

What are dielectric fluids?

Dielectric fluids are already around for some time in electrical engineering, serving as insulating oils in high-voltage equipment. Dielectric fluids prevent electrical discharges, enhance insulation, and dissipate heat, ensuring the reliability of power systems. Dielectric fluids also find use in cooling electronic components and industrial processes, requiring high-temperature stability. In recent years, dielectric fluids are increasingly considered for immersion cooling of servers in datacenters as an alternative to air cooling.

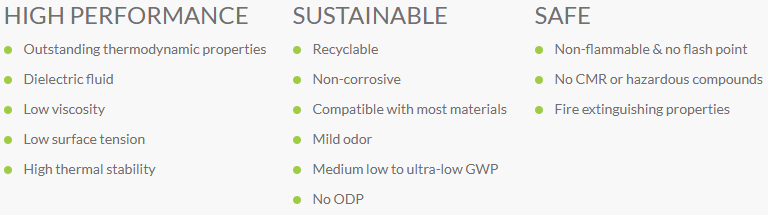

Why choosing THERMASOLV™ dielectric fluids?

Difference between single-phase and two-phase immersion cooling

Single-phase immersion cooling involves immersing electronic components in a dielectric liquid that remains in a single phase (liquid) throughout the cooling process. The liquid absorbs heat from the components, and the temperature of the liquid rises. The heated liquid is then circulated or pumped to a heat exchanger where the heat is transferred away, keeping the components cool. This method is typically simpler and more cost-effective but may not be as efficient in handling higher heat loads.

Two-phase immersion cooling, on the other hand, uses a dielectric liquid that undergoes a phase change from liquid to vapor as it absorbs heat. The heat causes the liquid to evaporate, and the vapor rises to a condenser, where it cools and condenses back into liquid form. This phase change allows for more efficient heat absorption and heat transfer, making it better suited for high-performance computing or systems with higher heat dissipation needs. It’s more complex but offers greater cooling capacity and efficiency.

Read more

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 7 results

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

-

-

-

-