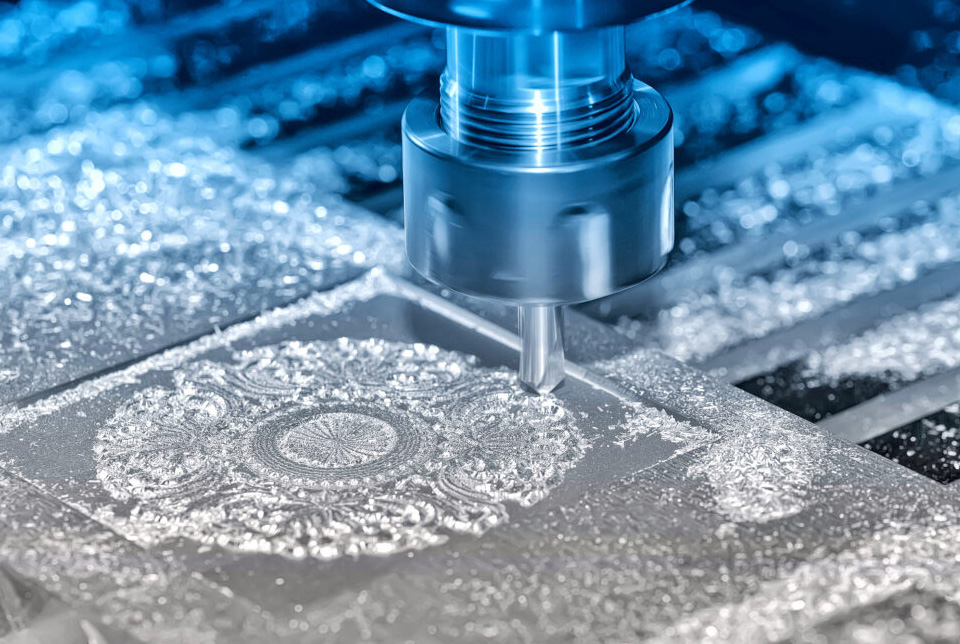

Particles Removal

Solutions to remove with high accuracy various particles from metals & plastics, according to your desired process.

Industrial Particle Removal Solutions for High-Precision Cleaning

Particle removal is a critical step in industrial cleaning processes, especially within the automotive, aerospace, and medical sectors. These industries demand high standards for product quality, operational precision, and component reliability to maintain safety and compliance.

Certain machined parts must be completely free from particles to meet strict quality and reliability benchmarks. This is particularly vital for components involved in sensitive applications—such as inspection devices or oxygen delivery systems—or when preparing parts for subsequent high-precision operations like machining in white or grey rooms, gluing, coating, or painting.

To effectively reduce the number and size of particles, INVENTEC offers specialized cleaning solutions tailored to customer needs and industry standards. Our comprehensive range of cleaning processes includes immersion, spraying, and flushing methods, all available with either aqueous or solvent-based cleaning fluids, while ensuring compliance with stringent environmental regulations.

Key Benefits of INVENTEC’s Particle Removal Solutions:

- Optimized for high-precision industries like aerospace, automotive, and medical

- Adaptable cleaning methods: immersion, spraying, flushing

- Compatible with aqueous and solvent-based cleaning fluids

- Environmentally responsible formulations meeting regulatory standards

Our Top Particles Removal Products

| Process | Method | Product Solution |

|---|---|---|

| Solvent | Co-Solvent | Not Recommended Process |

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum | Not Recommended Process | |

| Aqueous | In-chamber aqueous spray |

|

| Inline aqueous spray |

|

|

| Aqueous immersion with submerged jets |

|

|

| Aqueous ultrasonic immersion |

(used for injectors / particle control) (particle removal in 3D printing) (PFAS-free) |

|

| Manual |

|

|

Above table is a non-exhaustive list. INVENTEC offers additional particle removal products, including improved or customized formulations tailored to specific industrial needs. Use our product search or contact our team for expert guidance.

What are the different processes?

- Co-solvent: process using Topklean products for cleaning and fluorinated blends for rinsing

- Mono-solvent: vapor-phase cleaning using a single solvent for both cleaning and rinsing

- In-chamber aqueous spray: dishwasher-type system

- Inline aqueous spray: continuous cleaning using spray nozzles in a tunnel system

- Aqueous immersion with submerged jets: immersion in a bath with agitation by circulating submerged jets

- Aqueous ultrasonic immersion: immersion in a tank equipped with ultrasonics, with or without basket agitation

- Manual cleaning: spraying, flushing with recirculation, or soaking in a simple unheated tank. Manual mechanical action with brush or swab is possible

INVENTEC is a trusted partner in industrial cleaning, providing advanced particle removal solutions tailored for critical manufacturing sectors. Our technologies support reliability, safety, and compliance across every step of your production process.

See Other Cleaning Solutions Discover our guide Read FAQ

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Showing all 15 results

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

-

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

QUICKSOLV FIDES

- Oil & dust removal for dielectric cleaning

- For manual spray equipment

- Safe & fast cleaning under power

-

-

-

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

-

3M NOVEC 7100

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- Very low surface tension

Alternative: PROMOSOLV NEO A1

-

3M NOVEC 73DE

- Removal of a wide range of contaminants

- Vapor phase process

- Very low HSE impact & very low surface tension

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 72DE

- Removal of a wide range of contaminants

- Vapor phase process

- High cleaning power & very low GWP

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 71DE

- Removal of a wide range of contaminants

- Vapor phase process

- Medium cleaning power

Alternative: PROMOSOLV NEO B1

Discover our High-Performance Solution for Precise Particle Removal!

QUICKSOLV DEF 90

- Multi-purpose cleaner

- Manual cleaning

- Non-flammable

- Removal of all type of organic residues

Particles Removal

Industrial Cleaning Solutions

Frequently Asked Questions (FAQ)

What is particle removal in industrial cleaning?

Particle removal is the process of eliminating solid contaminants such as dust, metallic fragments, machining residues, or other fine particles from component surfaces. This step is critical to maintain product quality and ensure compliance with cleanliness specifications.

Why is particle removal important?

Even microscopic particles can cause defects, reduce the lifespan of components, or interfere with processes like coating, bonding, and assembly. Effective particle removal improves reliability and overall performance.

Which materials can benefit from particle removal?

Particle removal is essential for metals, plastics, ceramics, and composite materials used in industries such as automotive, aerospace, electronics, and medical devices.

What methods are used for particle removal?

Common methods include aqueous cleaning, solvent cleaning, ultrasonic cleaning, high-pressure spray systems, and air blow-off techniques. The choice depends on part geometry, contamination type, and required cleanliness level.

How is cleaning performance verified?

Verification methods include gravimetric analysis, optical inspection, particle counting, and surface analysis to ensure the process meets cleanliness standards. For assessing particulate contamination, standards such as SAE AS4059 (e.g. NAS 1638) are commonly used as references, especially in the aerospace, automotive, and medical sectors.

Can particle removal be integrated into automated production lines?

Yes. Modern cleaning systems are designed for integration with automated processes, ensuring consistent results and minimizing manual handling.

Does INVENTEC provide solutions for particle removal?

Yes. INVENTEC Performance Chemicals offers cleaning chemistries and process support to achieve high-precision particle removal while protecting sensitive substrates.

Where can I get advice on selecting the right particle removal process?

Industry experts, including INVENTEC’s technical team, can help assess contamination challenges, recommend appropriate cleaning methods, and ensure environmental compliance.

What are the main challenges in particle removal?

Challenges include removing particles from complex geometries, ensuring no recontamination, handling sensitive materials, and balancing cleaning efficiency with environmental and safety considerations.

How can particle removal impact downstream processes?

Effective particle removal enhances adhesion for coatings, improves soldering or bonding reliability, prevents malfunctions in precision components, and reduces the risk of defects in final assembly.

Particle Removal Solutions: High-precision cleaning for metals & plastics

Particle removal solutions are essential in industrial cleaning where even microscopic contaminants can compromise the reliability, performance, or longevity of components. These processes ensure that metals and plastics are cleaned to the highest standards required by advanced industries.

Depending on the process requirements, techniques such as ultrasonic cleaning, spray rinsing, immersion cleaning, or precision solvent cleaning are employed to achieve accurate particle removal without damaging the base materials.

Industries such as automotive, aerospace, medical devices, and semiconductors rely on particle-free surfaces to guarantee safety, precision, and product reliability.

Benefits & Applications

Key BenefitsParticles Removal solutions ensure the precise elimination of dust, micro-debris, and solid contaminants from metals, plastics, and other sensitive surfaces. By optimizing Particles Removal in production and maintenance, the risk of defects, conductivity failures, or coating issues is minimized. Consistent cleanliness also supports higher reliability in high-tech manufacturing.

Technical AspectsParticles Removal can be achieved through controlled airflows, liquid-based rinsing, solvent-assisted cleaning, or advanced methods such as ultrasonic and plasma processes. Each Particles Removal technique is designed to target specific contaminants while preserving the integrity of the substrate. High-precision Particles Removal systems are compatible with both manual and automated production lines.

ApplicationsParticles Removal plays a critical role in electronics manufacturing, semiconductor processes, optics production, and medical device assembly. Removing particles from metals and plastics helps ensure strong adhesion of coatings, reliable electrical performance, and contamination-free surfaces. Whether applied to PCB cleaning, power electronics, or precision components, efficient Particles Removal enhances overall product quality and longevity.

Particle Removal in Automotive Industry

Particle cleaning solutions are critical for engine components, electric vehicle batteries, and precision electronic modules. Removing metallic and plastic particles ensures durability, electrical performance, and safety of vehicles.

Particle Removal in Aerospace & Defense

In aerospace and defense systems, particle removal is crucial for avionics, hydraulic systems, and satellite components. Cleanliness standards are extremely high to ensure mission reliability and long-term durability in harsh environments.

Particle Removal in Medical Industry

For medical devices and implants, particle-free cleaning prevents contamination and guarantees patient safety. Applications include cleaning surgical instruments, endoscopic equipment, and precision plastic components.

Showing all 15 results

-

PROMOSOLV NEO A1

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- No GWP & PFAS free

- 3M Novec 7100 replacement

-

-

-

PROMOSOLV NEO B1

- Removal of a wide range of contaminants

- Vapor phase process

- PFAS free & no GWP

- 3M Novec 71DE, Novec 72DE, Novec 73DE, and Novec 8200 replacement

-

QUICKSOLV FIDES

- Oil & dust removal for dielectric cleaning

- For manual spray equipment

- Safe & fast cleaning under power

-

-

-

-

PROMOSOLV 70

- Removal of a wide range of contaminants

- Vapor phase process

- Very low GWP: 96

- 3M Novec 71DE, Novec 72DE, Novec 73DE replacement

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

-

3M NOVEC 7100

- Light oil & particles removal / rinsing & drying

- Vapor phase, co-solvent, flushing & drying process

- Very low surface tension

Alternative: PROMOSOLV NEO A1

-

3M NOVEC 73DE

- Removal of a wide range of contaminants

- Vapor phase process

- Very low HSE impact & very low surface tension

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 72DE

- Removal of a wide range of contaminants

- Vapor phase process

- High cleaning power & very low GWP

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 71DE

- Removal of a wide range of contaminants

- Vapor phase process

- Medium cleaning power

Alternative: PROMOSOLV NEO B1

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.