Electronic & Semiconductor Cleaning

Water- & solvent based cleaning solutions dedicated for the electronic assembly & semiconductor industry and suited for your desired process.

Select subsegment :

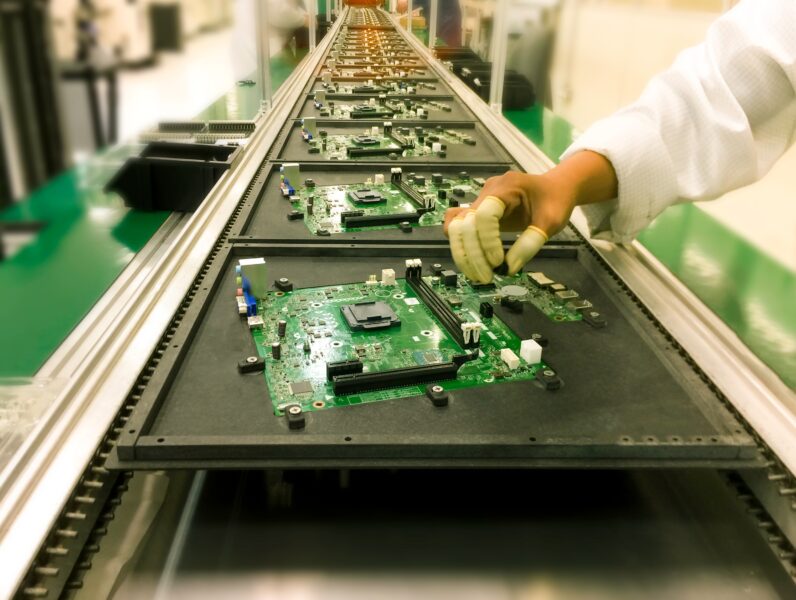

PCB Defluxing & Cleaning

Defluxing is crucial in cleaning solutions for removing residual flux and contaminants from semiconductor components, ensuring optimal performance and reliability of electronic devices.

In order to increase the reliability of your electronic assembly or to improve the adhesion of protective coatings after soldering, it is recommended to remove any remaining flux residues.

With respect to normative requirements and going beyond environmental regulations our products are suited to take up the challenges of todays technological evolutions like, miniaturization, low stand-off, sensitive components and difficult to clean no-clean solders.

INVENTEC has a broad range of products for defluxing PCB’s, components, leadframes, etc. We cover water- as solvent based cleaning processes, including our renowned co-solvent system which we launched 15 years ago and still today is regarded as one of the most environmental friendly, fastest and performing cleaning process available.

The table below shows our dedicated defluxing product, suited for your preferred process.

| Process | Process | Product Solution |

|---|---|---|

| Solvent | Co-Solvent |

CLEANING SOLVENT: |

|

RINSING SOLVENT: |

||

| Mono-Solvent (Vapor Phase) |

|

|

| Vacuum |

|

|

| Aqueous | Spray in Air |

|

| Spray in Line |

|

|

| Immersion Jets |

|

|

| Immersion Ultrasonics |

|

|

| Manual |

|

Above table is a non exhaustive list. INVENTEC offers more products which could be older and for which we have an improved formulation or a fine-tuning to a specific need. You may find a specific product via our search option or contact us for more information.

What are the different processes?

- Co-solvent: solvent process with Topklean products as cleaning agent and Hydrofluoroethers as rinsing solvent

- Mono-solvent: vapor phase cleaning with 1 single solvent for cleaning & rinsing

- Aqueous spray in air: dishwasher concept

- Aqueous spray in line: spray in air as part of a continous production process

- Aqueous immersion jets:parts are submerged in a cleaning bath and immersed spray jets provide agitation

- Aqueous Immersion : immersion in tank with options for heating, ultrasonics, agitation (moving of cleaning baskets)

- Manual cleaning: spray, poor or dip in simple tank without heating

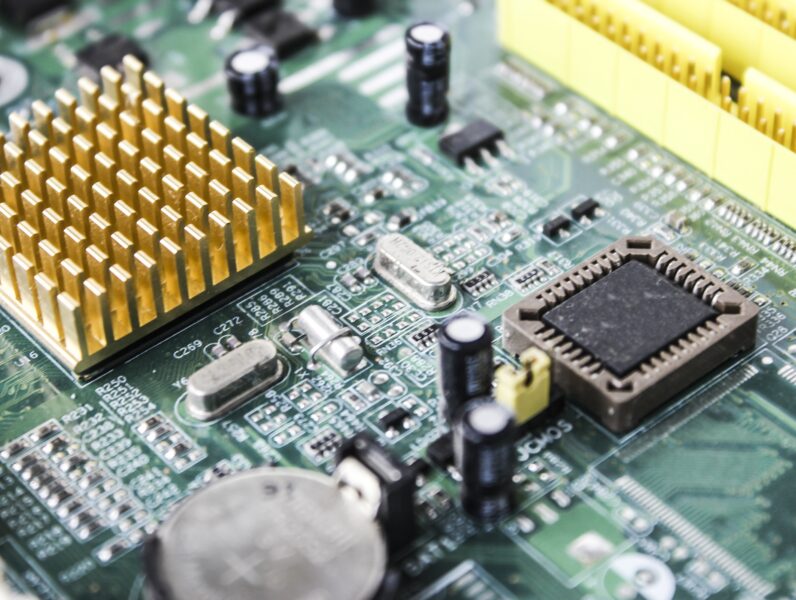

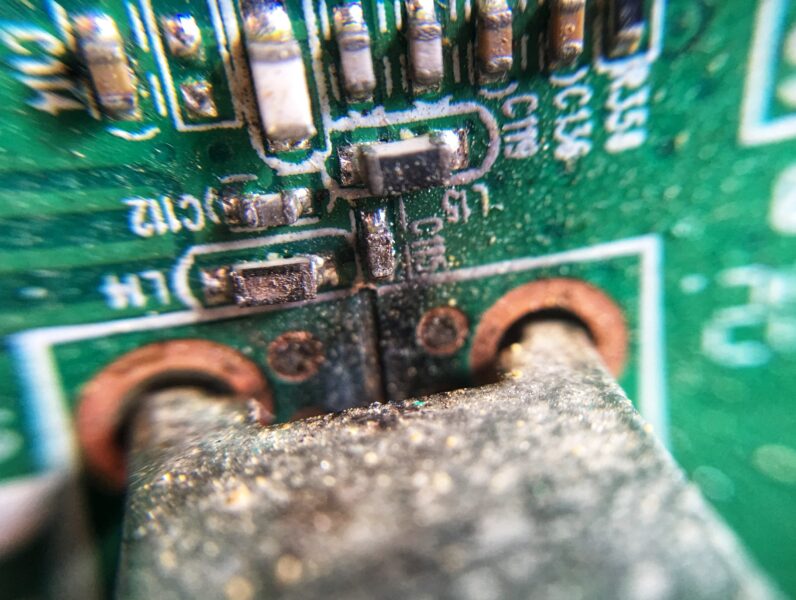

Power Electronics Cleaning

Cleaning power electronics is vital to ensure optimal performance and longevity by preventing the buildup of dust, dirt, and other contaminants that can interfere with heat dissipation and electrical connections

Cleaning power electronics is essential for maintaining their performance and extending their lifespan. Over time, dust, dirt, and other contaminants can accumulate on the surfaces of power electronics, especially on components like circuit boards, connectors, and heat sinks. This buildup can lead to poor heat dissipation, which may cause components to overheat and malfunction. By regularly cleaning these components, you ensure that they continue to operate at peak efficiency, reducing the risk of thermal damage and electrical short circuits.

In addition to improving performance, cleaning power electronics helps prevent costly repairs or replacements. Contaminants can also affect the electrical connections, leading to intermittent faults or complete failure. INVENTEC offers advanced cleaning solutions and products specifically designed for power electronics, helping to remove contaminants without damaging sensitive components. Their solutions enhance the longevity, reliability, and overall efficiency of power electronic systems, ensuring reliable operation in critical applications, such as renewable energy systems, industrial machinery, and telecommunications.

Regular cleaning with INVENTEC products thus helps maintain the high performance of power electronics while reducing maintenance costs.

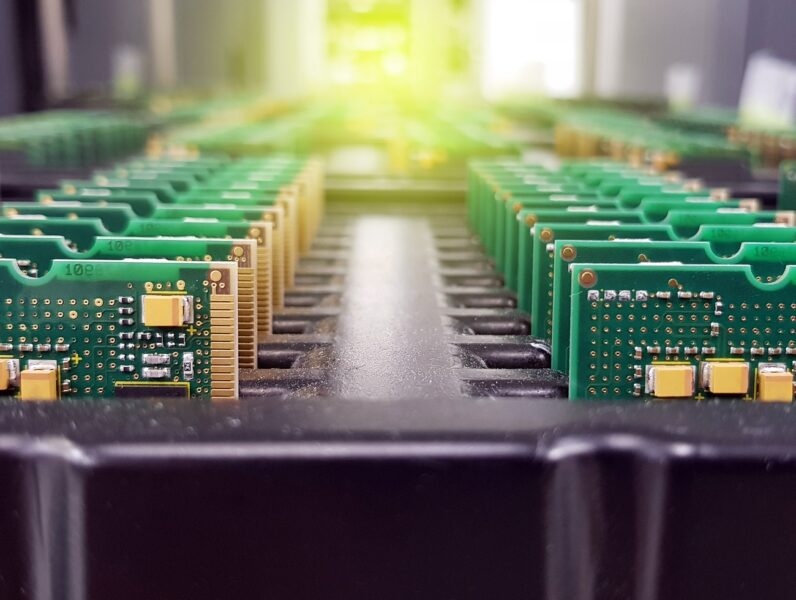

Package Cleaning

Package cleaning in semiconductor cleaning solutions plays a key role in removing contaminants from BGAs, CMOS and flip chips, which can affect device performance, yield, and reliability during the final stages of production.

In semiconductor manufacturing, effective package cleaning is a critical process to ensure the optimal performance and reliability of devices like BGAs, CMOS and flip chips. Contaminants such as particles, flux residues, and other impurities can negatively impact electrical performance and overall device yield. Therefore, removing these contaminants during the final stages of production is essential to maintaining high standards of quality and functionality.

INVENTEC offers a comprehensive range of cleaning solutions designed to address these challenges. Their portfolio includes both water-based and solvent-based cleaning agents that are specifically formulated to meet the rigorous demands of semiconductor packaging. These cleaning products are engineered to efficiently remove contaminants from delicate components while ensuring minimal damage and maximizing device reliability.

With INVENTEC’s advanced cleaning solutions, manufacturers can maintain the highest levels of quality control throughout the production process.

Maintenance Cleaning

Maintenance cleaning in electronics and semiconductors is essential for preventing contamination, enhancing performance, and prolonging the lifespan of delicate components.

To ensure a reliable production process and a long life-time of the equipment, maintenance cleaning is an important step not to overlook.

Typical contamination to be removed are burnt-in fluxes, condensed gas emissions and coatings on equipment, frames, pallets and conveyors. Also specific solutions for cleaning dispensing needles are required.

Our product are especially designed in order to guarantee a quick & easy cleaning process, so downtime of the production process is put at a minimum. All our maintenance products have a very low hazard risk & environmental impact, taking into account operators safety and health.

Read moreSMT Glue Cleaning

SMT glue removal is important in electronic and semiconductor cleaning to ensure proper component adhesion, prevent contamination, and maintain the performance and reliability of the final product.

The purpose of an adhesive is to bond 2 substrates firmly together. For this reason breaking the bond and removing the adhesive can be a difficult job.

As there are many different kind of adhesives on the market, we recommend to contact us with your specific application in case you want to remove cured adhesives.

Un-cured electronic adhesives however are more easier to clean and for this we have some proven products in our range.

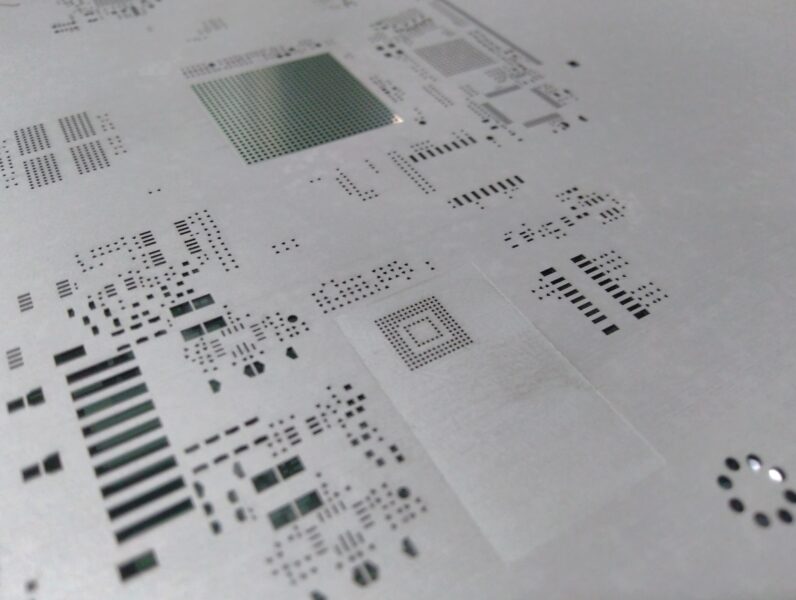

Read moreMisprint & Stencil Cleaning

Misprint and stencil cleaning in electronic cleaning helps maintain the accuracy and reliability of printed circuit boards by removing contaminants that could affect the quality of soldering and overall performance.

In order to avoid misprints and maintain a reliable production process, stencil cleaning is a standard operation in SMT manufacturing. Although manual cleaning can be used for low volume or prototyping, automatic processes are however recommended for large volume production.

When formulating these products, we have put great attention on fast cleaning cycles to minimize downtime, reducing water consumption and making sure the cleaning agent is not harmful to the cleaning equipment and stencils.

Also under stencil cleaning inside an SMT printer plays an important factor to maintain a reliable and consistent assembly process. For this application it is key the cleaning chemistry doesn’t change the viscosity of the solder paste when it comes in contact with the paste during the under stencil wipe cleaning. TOPKLEAN EL 7 is especially developed with this in mind and provide you with a low consumption & safe to use solution.

Read moreTechnical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.