TOPKLEAN EL 80

Co-solvent flux removal fluid

- Removal of flux residues

- Co-solvent process

- Improved overall performance

TOPKLEAN EL 80

Is especially designed to clean solder flux residues after reflow. While removing almost any solder flux residues, it also leaves no white residues and provides a shiny effect on alloys & metals.

It’s our latest development based on our new QSA technology, which allows faster solubilization of organic & mineral compounds. This product takes the lead in its application, thanks to its notable rise in flashpoint, facilitating safe cleaning at higher temperatures, improved cleaning efficacy, and lowered surface tension. It particularly excels in cleaning under very low stand-off components.

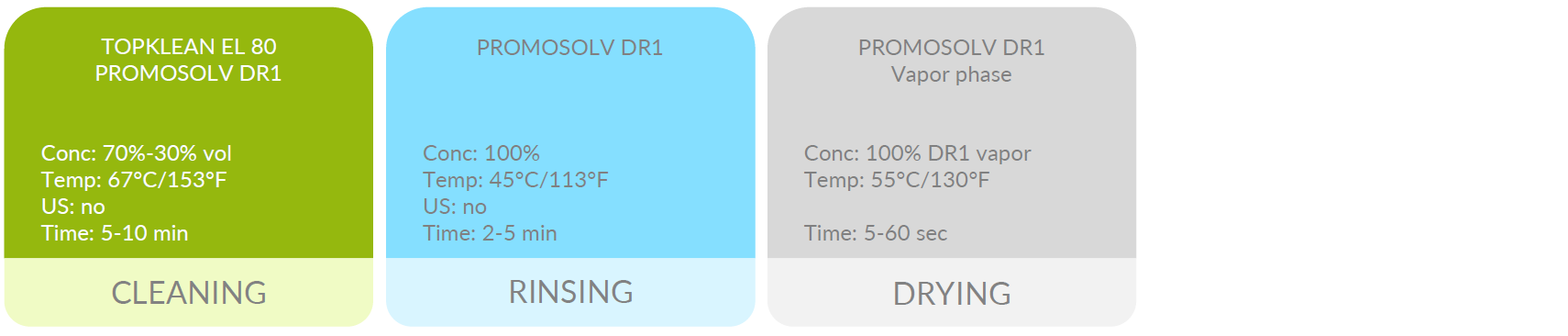

It is used in co-solvent process to offer a fast & sustainable cleaning process with very high cleaning efficiency. In this process, TOPKLEAN™ EL 80 is rinsed perfectly with solvents from our PROMOSOLV™ range.

The co-solvent process has been a game changer for over 15 years now and is qualified by several actors in the electronic & semicon industry. It has been developed to replace solvents with a high HSE impact with a more sustainable solution and with equally strong cleaning performance. It particularly stands out when addressing low stand-off components. In contrast, a water-based cleaning system carries the risk that the cleaning chemistry may not be adequately removed due to the significantly higher surface tension of water.

This is not a product

Although fully in line with safety & environmental regulations, this product doesn`t match our strict criteria to be labelled as a Greenway product.

LOOKING FOR A MORE SUSTAINABLE SOLUTION?

GREENWAY ALTERNATIVE

- We currently don`t have a Greenway alternative but our target is to develop one in the near future. In case you want us to prioritize the development of a Greenway alternative, do not hesitate to contact us.

Benefits

Performance

- Excellent solubility of organic & mineral residues

- Very low surface tension to allow excellent cleaning under low stand-off components

- High flashpoint which allows risk-free cleaning at elevated temperatures

- Excellent compatibility with materials used on PCB’s

- Allows shining effect to sensitive alloys & soldered surfaces

Cost

- Fast process allows increase in production capacity

- Rinsing fluid is constantly recycled, limiting consumption.

- No water consumption & no need for wastewater treatment

HSE

- Non-toxic & no CMR substances

- No Ozon Depletion Potential (ODP)

- No Global Warming Potential (GWP)

- Very high flash point – safe to use, storage & transport

- No aromatics & halogenated compounds