PROMOCLEAN TP 178

Removal of oxides, mineral residues and diamond liquid polishing

- Removing oxides, mineral residues & diamond liquid polishing

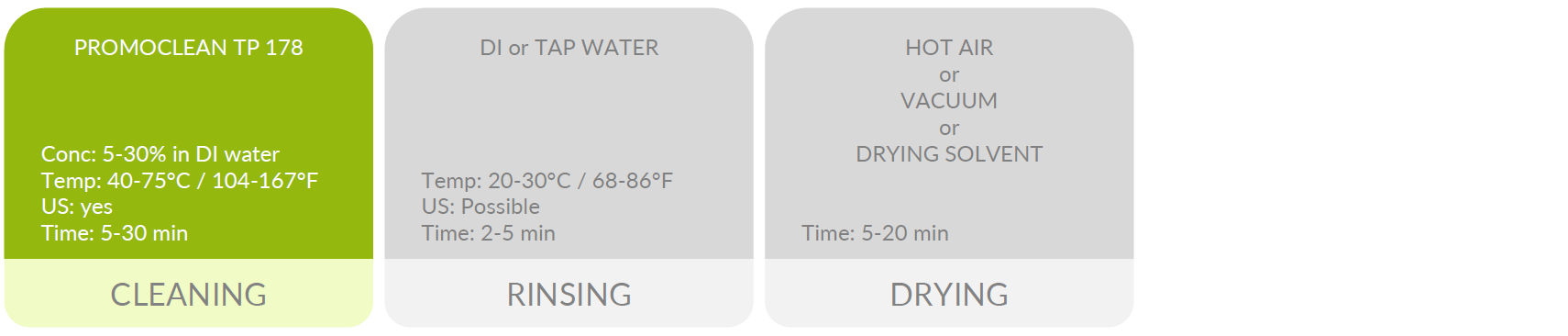

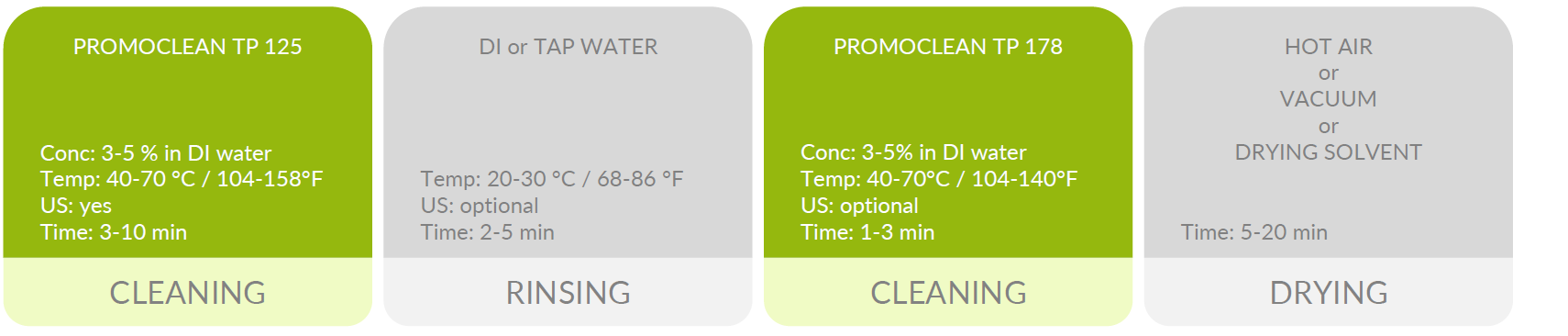

- Aqueous immersion process with ultrasonics

- Substitute for phosphoric acid based cleaners

PROMOCLEAN TP 178

PROMOCLEAN TP 178 is especially designed for removal of oxides, minerals residues (such as lime scale or finger traces) and diamond liquid polishing in an aqueous immersion process. Having an acid pH, it provides excellent cleaning performance and can be used on most metals such as Inox, ferrous alloys, Copper, Titanium, Aluminium, Gold & Silver.

This product can also be used as a brightening agent to make brass & light alloys more shiny. However, the right dilution and process parameters need to be confirmed. It is a concentrated product which is used diluted with DI water. Thanks to its excellent chelating properties it can be also diluted with tap water without risk of lime deposits.

From sustainability point of view, PROMOCLEAN TP 178 does not contain phosphorus compounds and helps to limit the ecological degradation of water bodies & rivers.

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable & no flashpoint, eliminating the need for explosion proof equipment or special storage & transport

- Non-toxic

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- No GWP

- No aquatic toxicity

- Does not contain phosphorus compounds

- No mineral acid

Benefits

Performance

- Excellent deoxidation power

- No risk of phosphating ferrous metals

- Compatibility with most metals, including sensitive ones

Cost

- High chelating power, reducing lime deposits

- High cleaning power even at low concentration

- Reduce the cost of wastewater treatment

HSE

- Non-toxic & no CMR substances

- Low environmental impact : No phosphorus compound

- No mineral acid such as hydrochloric nitric or sulfuric acids

Process examples

Diamond polishing compound removal (e.g. manufacturing of tungsten carbide cutting tools)

- Dry ferrous metals immediately after rinsing to avoid corrosion.

- A dedicated PCA Kit to monitor the bath status and compatibility report with different materials are available on request.

- It is key to determine the maximum time materials can be exposed to the cleaning chemical. Although our cleaning products will not damage materials they are designed for under normal conditions, prolonged exposure may.