PROMOCLEAN TP 1114

Removal of Polishing Pastes & Oils

- Oil & polishing paste removal with 1-3 days corrosion protection

- Aqueous immersion process

- Compatible with sensitive alloys

PROMOCLEAN TP 1114

Especially designed for removal of polishing pastes, hydrocarbon & water-soluble oils. It is dedicated for aqueous immersion process with ultrasonic agitation.Thanks to its medium pH , it doesn’t damage most ferrous and sensitive non-ferrous alloys, like Inox, Aluminium, Titanium, Copper, Brass. It can also be used on precious metals such as gold and silver.

Additional, PROMOCLEAN TP 1114 provides a medium temporary protection against corrosion thanks to its passivation properties. This makes the product particularly suitable for inter-operation before the next operational step, leaving the parts protected for 1-3 days (depending on environment conditions).

In case higher level of temporary protection is needed, we recommend PROMOCLEAN TP 1117.

PROMOCLEAN TP 1114 is qualified and used by several actors in the luxury watch, jewellery & medical parts manufacturing.

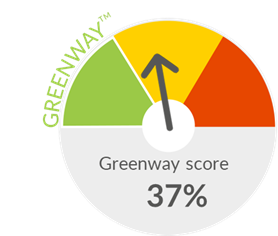

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable, no flashpoint & no EUH risk phrases: 100% safe for storage and when used in equipment

- Non-toxic

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- No GWP & Very low VOC (<25% of VOC compound)

- Made partially with renewable raw materials

Benefits

Performance

- Compatibility with most of sensitive metals

- Excellent dispersion of polishing compounds

- Does not leave spots or residues

- Good temporary protection against corrosion

Cost

- High cleaning power even at low concentration

- Very long bath-life

HSE

- Non-toxic & no CMR substances

- Low environmental impact

- Non flammable

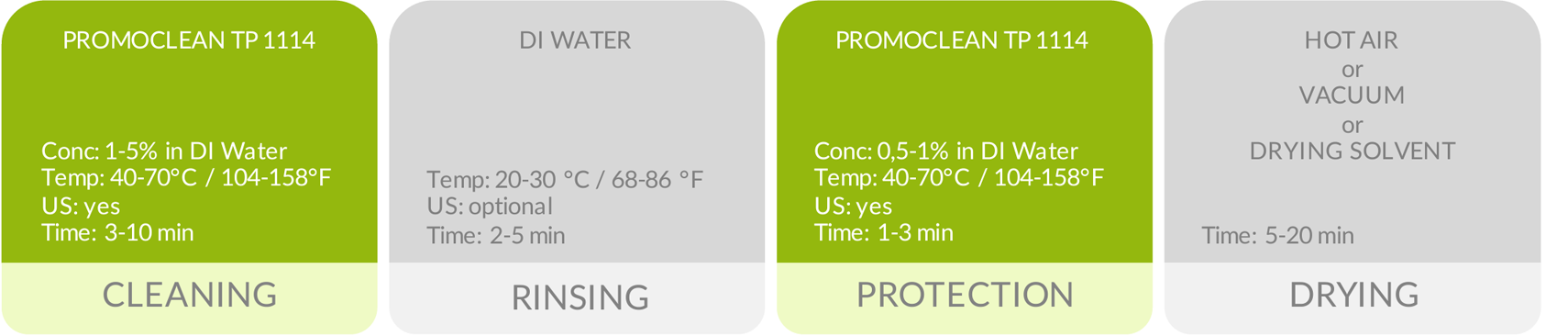

Process examples

Oil removal with temporary corrosion protection

- For cleaning hard to remove polishing pastes, other products from the PROMOCLEAN range could be used in combination with PROMOCLEAN TP 1114 in order to improve process efficiency.

- Increasing the bath-life of your process can be achieved by adding an oil separator within the cleaning equipment and to add periodically concentrated product.

- Compatibility report with different materials is available on request.

- Concentration can be monitored with a dedicated PCA KIT or with our PCA DIGITAL online analysing equipment.

- It is key to determine the maximum time materials can be exposed to the cleaning chemical. Although our cleaning products will not damage materials they are designed for under normal conditions, prolonged exposure may.