PROMOCLEAN DISPER 800

Aqueous defluxing fluid

- Removal of flux residues

- Aqueous spray process

- Fast & high power cleaning

PROMOCLEAN DISPER 800

Is especially designed for removal of all types of flux residues on PCBA’s, Power modules, lead frames, BGA’s, PoP or SIP applications & LED assemblies.

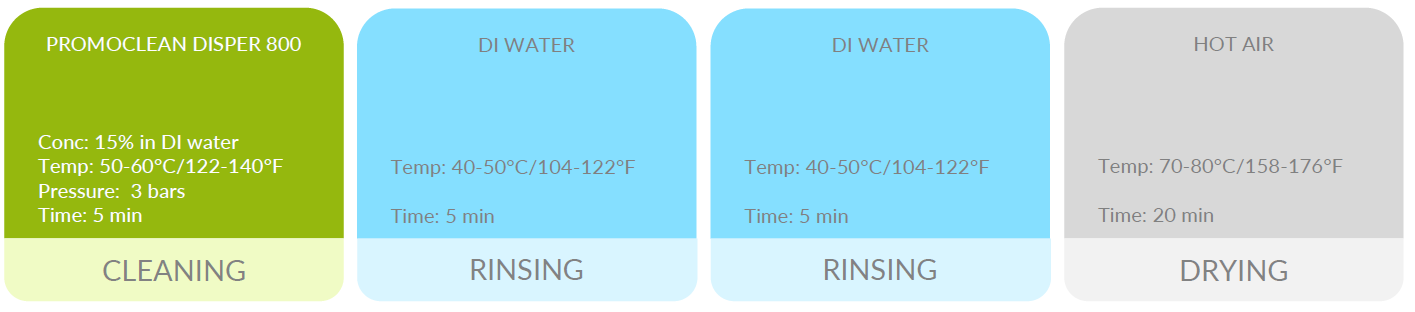

It’s our latest development based on our new QSA technology, which allows faster solubilization of organic & mineral compounds. Thanks to this and its excellent antifoam properties, PROMOCLEAN DISPER 800 is especially suitable for spray-in-line processes. Naturally, it can also be used for batch spray processes like, spray-in-air or immersion jet.

The controlled pH mechanism makes sure this product is compatible with aluminum, copper & other sensitive materials and at the same time providing a high cleaning power. Its low surface tension allows very well cleaning and rinsing under low stand-off components and difficult to reach spaces.

It’s a concentrated product which is used diluted with DI water and has excellent cleaning power from 10 % dilution.

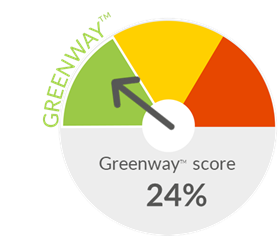

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable & no flashpoint -> eliminating the need for explosion proof equipment or special storage & transport

- Low corrosive impact

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- No GWP

- Non-corrosive for equipment

- Low environmental impact: no H labelling regarding environment

Benefits

Performance

- Excellent solubilization of reflowed organic compounds

- High rinsing capacity

- No foaming

- Removes also oxidation residues on copper aluminum & sensitive materials

- Suitable for high production rates

Cost

- High cleaning power even at low concentration

- Exceptional long bath-life

- Concentrated product, reduce transport & storage cost

HSE

- Non-toxic & no CMR substances

- Low environmental impact: GREENWAY product

- Non-flammable

- Non-corrosive