PROMOCLEAN DISPER 610

Removal of Baked-On Flux Residues & Recondensed Gas Emissions

- Removal baked-on flux residues

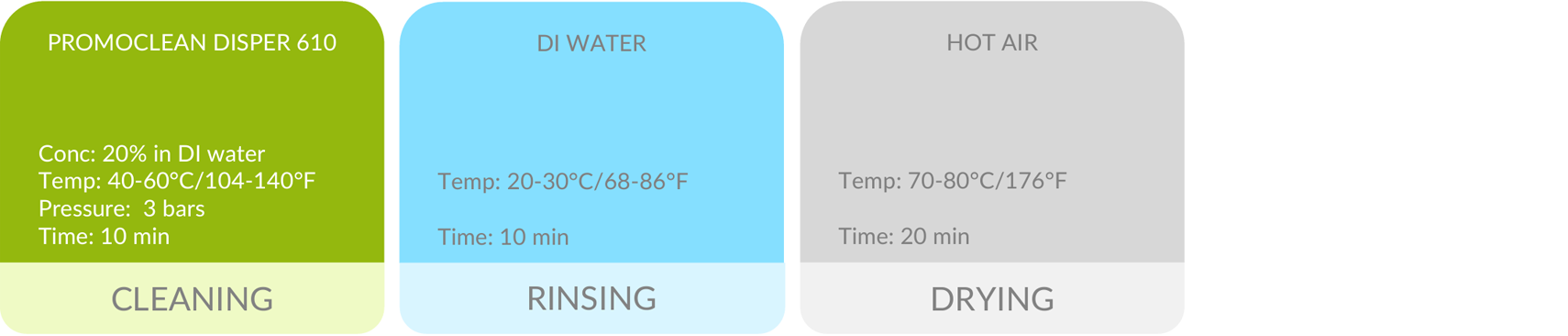

- Aqueous spray process

- Compatible with aluminium

PROMOCLEAN DISPER 610

Is especially designed for removal of all types of baked-on flux residues and recondensed gas emissions for maintenance purpose on electronic manufacturing equipment like wave frames, solder pallets, reflow oven condensation traps, etc.

Thanks to its excellent antifoam properties it is dedicated for water-based spray-in-air and immersion jet processes. Due to the controlled alkalinity, this product is compatible with aluminium & other sensitive materials.

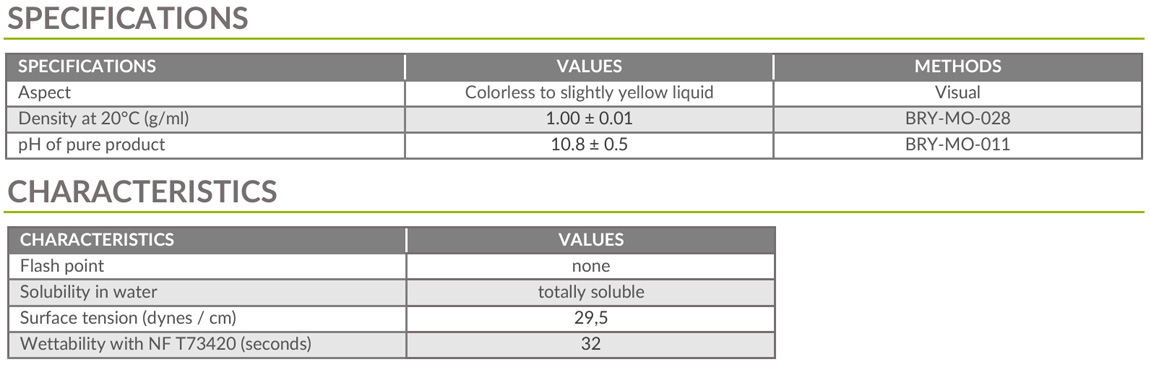

It’s a concentrated product which is used diluted with DI water and has excellent cleaning power from 20 % to 30 % dilution.

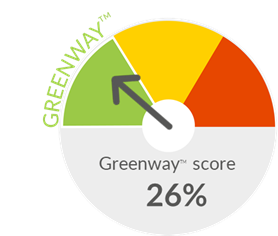

This is a product

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-flammable & no flashpoint -> eliminating the need for explosion proof equipment or special storage & transport

- Non-toxic

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- No GWP

- Very low VOC (<25% of VOC compound)

- Contains partial vegetable raw materials

Benefits

Performance

- Excellent solubilization of reflowed organic compounds

- High rinsing capacity but rinsing is optional

- Very low foaming

- Protects aluminum & sensitive materials during the cleaning cycle

Cost

- High cleaning power

- Excellent Long bath-life

- Concentrated product, reduce transport & storage cost

HSE

- Non-toxic & no CMR substances

- Non-flammable

- Low environmental impact: GREENWAY product