ECOREL SINTEC XP95D

Pressureless Sintering Process

- AG Sintering Paste

- Pressureless Sintering

- Dispensing

ECOREL SINTEC XP95D

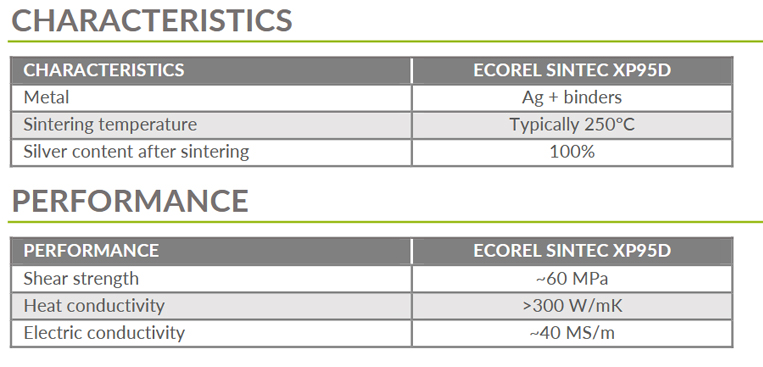

Is a pressureless sintering paste, designed for die-attach and applied by dispensing. As no pressure is required during sintering, standard reflow oven equipment can be used.

It ensures optimal wetting on different DCB and AMB surface finish (Cu, Au, Ag) and is compatible with the temperature requirement mission profiles of wide band gap material SiC and GaN.

Based on Nano-Join technology, ECOREL™ SINTEC XP95D exhibits superior levels of thermal conductivity and shear strength. Typical applications are found in the field of high-power die-attach, RF devices and power-LED.

Our sintering pastes does not contain halogen or nanoparticles and can be stored at room temperature without affecting the workability.

Benefits

PERFORMANCE

- High thermal conductivity to offer great heat dissipation

- Higher silver content without agglomeration risk

- High reproducibility and stability for dispensing

- Very good wetting on all surface finishes

- High shear strength for improved reliability

- 100% silver content post-sintering

- TCT -55°C-+ 125°C >1000 cycles

COST

- Can be used in standard reflow oven equipment

- More than 10h work-life with very stable dispensing performance

- Room temperature storage

HSE

- Lead free

- No CMR containing substances

- No halogen

- No nano particles

- REACH & RoHS compliant

Process Recommendation

The best process will depend on factors such as operating conditions, equipment, board or component design. Our team is ready to advise you.