ECOREL SINTEC AP90

Low Pressure Sintering Process

- AG Sintering Paste

- Low Pressure Sintering

- Printing

ECOREL SINTEC AP90

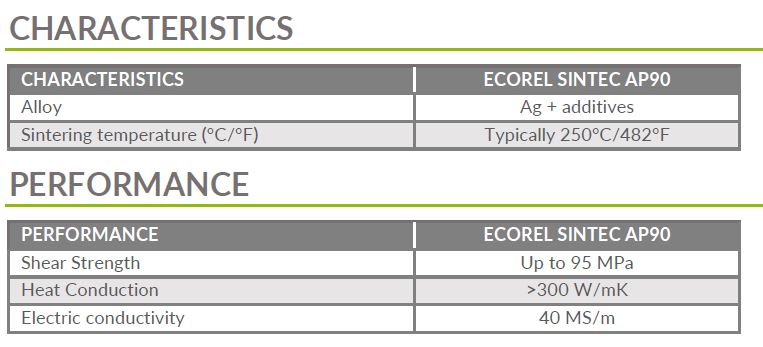

Is a low pressure sintering paste, with silver as its main component and dedicated for stencil printing process. It has been developed for die-attach and high power packages and allows only 1 step for complete module assembly. It offers lead free interconnections for large base plate sintering or components with die size up to 400mm2 onto DCB materials, gold, nickel, copper and silver surfaces.

Compatible with the temperature requirement mission profiles of wide band gap material SiC and GaN.

The sintering paste does not contain halogen nor nano particle and exhibits a very high shear strength. Besides, it can be stored at room temperature without evolution of characteristics.

Benefits

PERFORMANCE

- High thermal conductivity to offer great heat dissipation

- Higher silver content than state-of-the art sinter pastes without agglomeration risk

- Stable over long print-runs without degradation

- Very good wetting on all surface finishes

- High shear strength for improved reliability

- TCT -55°C-+ 125°C >1000 cycles

COST

- All-in-one sintering reduces overall process cost

- Increase lifetime and reliability of your product, hence reduces risk of premature failures

- Room temperature storage

HSE

- Lead free

- No CMR containing substances

- No halogen

- No nano particles

Process Recommendation

The best process will depend on factors such as operating conditions, equipment, board or component design. Our team is ready to advise you.