Powertrain

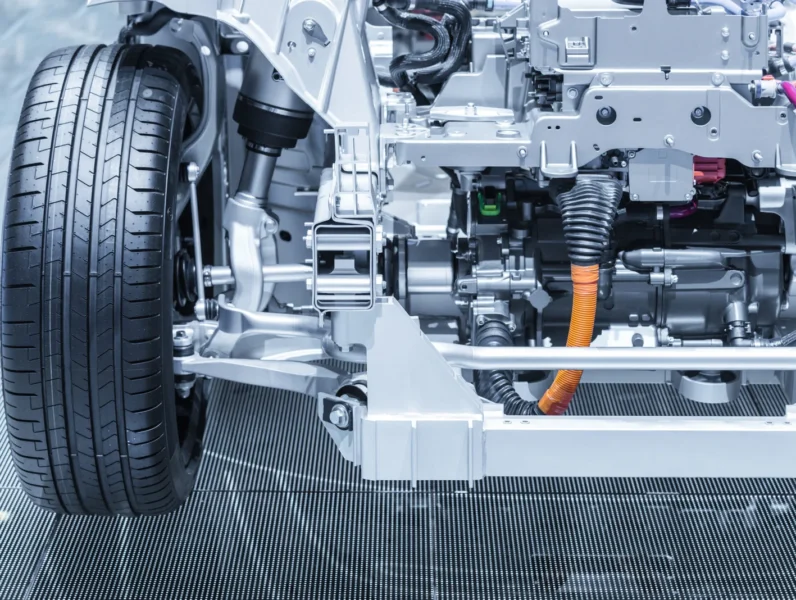

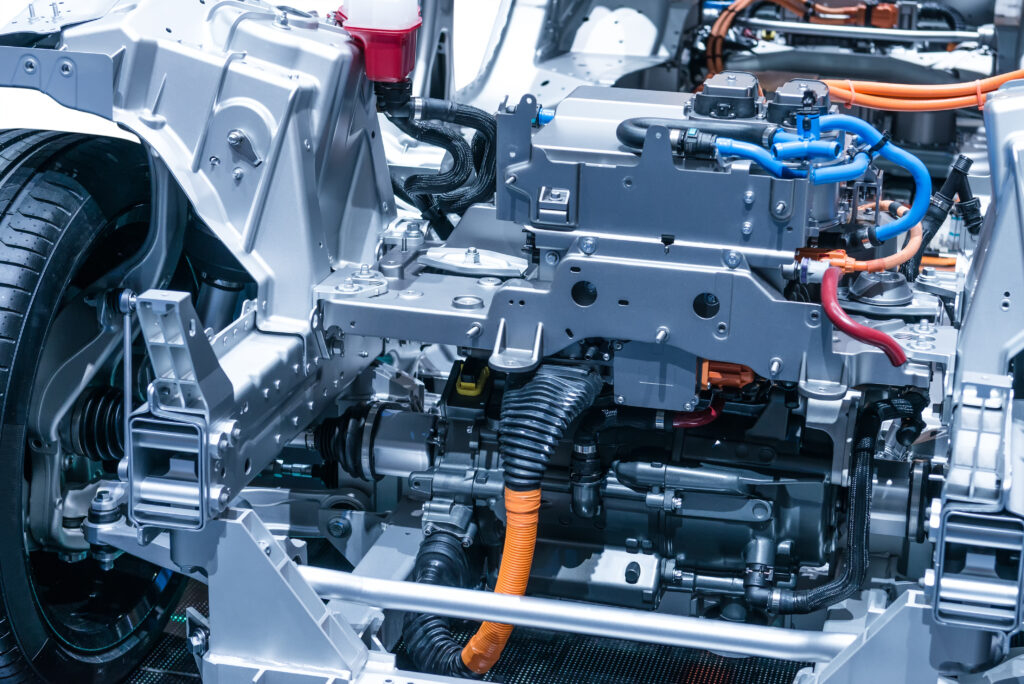

The powertrain encompasses every component that converts the engine’s power into movement. This includes the engine, transmission, the driveshaft,differentials, axles; basically anything from the engine through to the rotating wheels.

Typically these parts are exposed to high operating temperatures and temperature fluctuations, so from a soldering and coating perspective the materials should withstand these temperatures fluctuations and favourable optimize the heat dissipation.

Also wherever possible, light weight metals are used like aluminium which may ask for special attention when selecting cleaning agents.

Read more

Select subsegment :

INVENTEC Automotive Powertrain Solutions

INVENTEC specializes in providing high-performance soldering, cleaning, coatings, and cooling solutions tailored for the automotive sector, with a strong emphasis on powertrain applications. We offer a comprehensive range of chemical products designed to meet the stringent demands of automotive manufacturers, ensuring optimal performance and reliability in every aspect of the powertrain.

From soldering solutions that guarantee precise connections and durability, to advanced cleaning agents that ensure thorough removal of contaminants, our products are engineered to enhance the longevity and efficiency of powertrain components.

Our coatings solutions play a critical role in protecting automotive powertrains from corrosion and wear, offering long-lasting protection under harsh conditions. By focusing on the specific needs of automotive powertrains, we deliver custom-engineered solutions that integrate soldering, cleaning, coatings, and cooling technologies to optimize the overall efficiency and reliability of your powertrain systems.

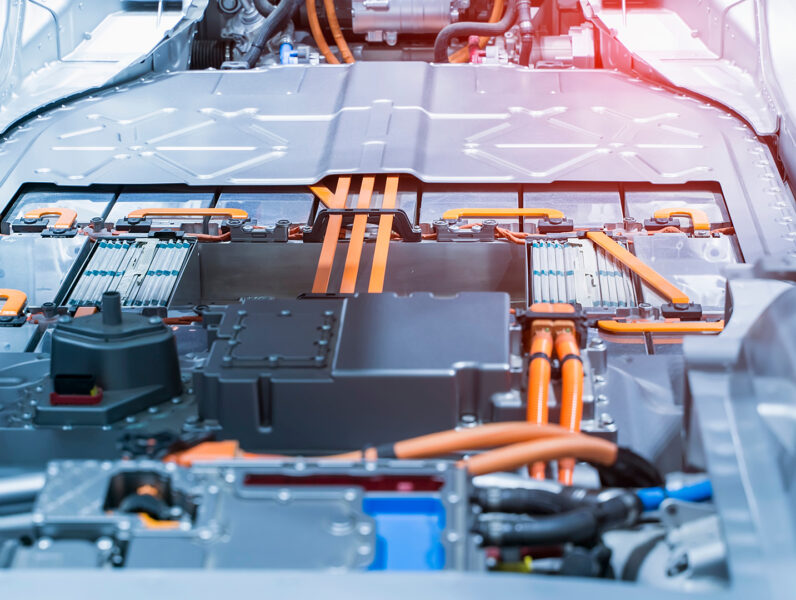

Powertrain Electronics with Low Void Solder for Better Heat Dissipation

Electric motor, power controller, inverter, converter and other electronics related to the powertrain of an electric car are during operations exposed to high temperatures. Not only by the heat generated by moving parts but also due to the high power on which they operate. In ICE cars there is a similar exposure to high temperatures and refers to all electronics which are located under the hood.

Voids in the solder joint reduces the thermal dissipation and hence the reliability of the assembly. Using a paste especially developed to minimize the amount and size of voids under specific sensitive components is recommended and will improve the overall reliability.

Discover our low void solutions

Contact an expert

Oil & Grease Removal on Aluminium and Light Alloys Powertrain

Weight is key in automotive so when possible light weight aluminium or other alloys are used. When oil or grease need to be removed, choosing the right cleaning agent is critical as aluminium and other light alloys are quite sensitive. They could be damaged when using a non adapted cleaning product.

Solvent systems are mostly harmless to all metals but for water based cleaners caution is required. We offer water based cleaners especially designed to remove Oil & Grease from sensitive metals. Despite some of them having a medium to high alkaline pH to allow efficient cleaning, they don’t damage these metals.

INVENTEC has developed a full range of cleaning agents for removal of Oils & Grease suited to you desired process.

Discover our oil removal solutions

Discover our grease removal solutions

Read morePCB Coatings for Enhanced Powertrain Reliability

In order to extend the life time of your electronic assembly and protect it against harsh environments they operate in, coating is a valuable option. Also they can provide additional mechanical strength to the assembly by absorbing vibrations.

INVENTEC offers several Conformal Coatings & Ultra-thin coatings. Ultra-thin coatings offers a more simple and cost advantage process, while traditional conformal coatings provide a more rigid protection. They both can be applied by selective spray or by dipping.

Although heat curing of conformal coatings is still very popular, we believe in the future of UV curing. Especially by using UV LED instead of the traditional mercury UV lamps, which is a more stable, cost-efficient and environmental processes.

When applying a protective coating it is also advised to clean prior to the coating process in order to maximize the coating adhesion. With INVENTEC you have a partner which can offer you soldering, cleaning and coating solutions. Designed to be compatible with each other to minimize the risk of compatibility issues.

Discover our coating solutions

Contact an expert

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.