Lighting

As external lighting in automotive does not only add to the driving comfort but also is a key safety feature, it requires reliable solutions in order to prevent premature failure.

LED’s are commonly used today due to their great performance, design flexibility and reduced energy consumption. However, LED’s require special attention in terms of heat management and may need coatings to protect it against exposure to harsh environments.

Also as a vehicle undergoes constant vibrations, choosing a solder alloy better resistant to vibrations may enhance the reliability of your product.

Read more

Select subsegment :

INVENTEC Automotive Lighting Solutions

INVENTEC specializes in providing advanced soldering, cleaning, coatings, and cooling solutions tailored to the automotive sector, with a particular focus on automotive lighting.

Through our innovative precision soldering solutions for complex lighting assemblies, our solutions are engineered for reliability and efficiency. Our chemical cleaning agents ensure that every component is thoroughly prepared, enhancing the longevity and functionality of automotive lighting systems.

In addition to soldering and cleaning, our specialized coatings are formulated to protect automotive lighting from harsh environmental conditions, ensuring durability and longevity. These coatings safeguard against corrosion, UV degradation, and other potential hazards, extending the life of lighting components.

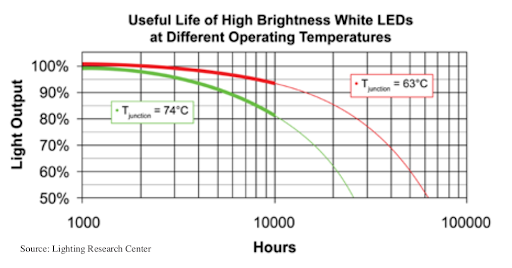

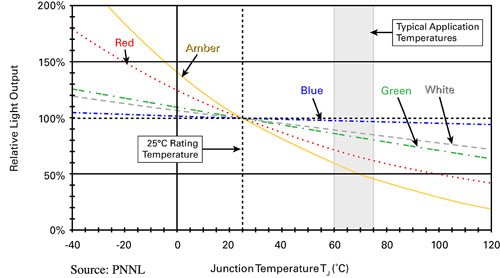

Low voiding paste for high power led

Heat dissipation in LED’s, especially in high power LED’s, is an important factor to maintain an optimal light output. Higher junction temperatures reduces light output, in particularly the amber and red wave lengths. Secondly, poor thermal management will accelerate the gradually decrease of light output over time.

It’s commonly known that voids in the solder, decreases the ability to dissipate the heat at the junction of the LED assembly. Using solder materials who are designed to keep voiding to a minimum is therefore recommended. In automotive this is specifically significant for front LED lighting.

Discover our low void solutions

Read moreLow & No silver alloys for rear automotive lights

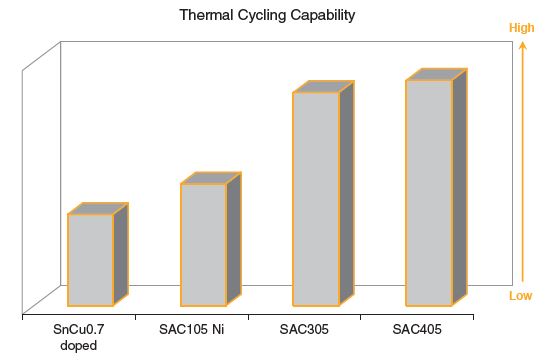

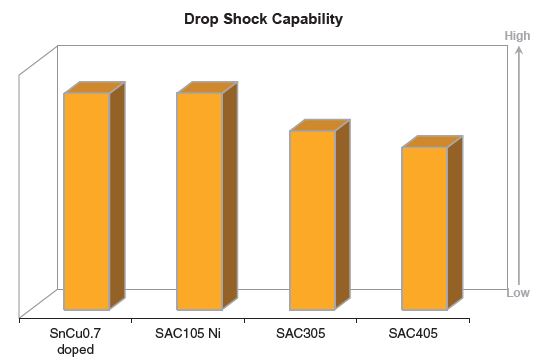

The fluctuating silver price, which is currently again on a high level, makes it difficult to keep cost under control. Low silver alloys could for devices not exposed to high thermal stress, a valuable alternative for SAC305 alloys. Typical we look for electronics placed inside the passenger compartment.

The wetting behaviors of low-silver alloy SnAg1.0Cu0.5 are comparable to a considerable degree with eutectic standard SnAg3.0Cu0.5 and can be in many cases used as a “drop in” solution. Not only cost could be a decision factor but also the drop and vibration resistance of a low silver alloy compared to SAC305 could favor these alloys. Low silver alloys are the number one choice these days for handheld devices, particularly for this reason.

Discover our Low & No silver solutions

Contact an expert

Ultra-thin coatings to extend life-time of LED’s

LED’s used for outside applications and exposed to weather conditions and humidity or placed in a harsh environments, can benefit greatly from coating them with an Ultra-thin coating. The higher the power of the LED, the more risk to dendrite growth and corrosion when exposed to humidity.

Ultra-thin coatings are only around 1 micro thick but provide sufficient protection against unwanted influences from the environment. These coatings will create no loss of light emissions or color changes.

Part of the LED module or the whole assembly can be simply dipped in the coating. This provides you with a simple and fast process. The coating dries in ambient air in a few seconds.

In automotive, target applications are the external lights, especially the high power front lights.

Discover our Ultra-thin coating solutions

Contact an expert

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.