Hearing Aid Devices

Soldering, cleaning and coating solutions to support the miniaturisation of hearing aid devices

Select subsegment :

INVENTEC Hearing Aid Devices Solutions

INVENTEC specializes in providing advanced soldering, cleaning, coatings, and cooling solutions through a range of high-performance chemical products tailored for the medical sector. With a specific focus on hearing aid devices, we offer precision solutions that ensure reliable, long-lasting performance for these critical devices.

Our soldering solutions are designed to support the intricate manufacturing process of hearing aids, providing strong, durable connections for sensitive components. Paired with our state-of-the-art cleaning agents, we help maintain the highest standards of hygiene and functionality, ensuring hearing aids remain free from contaminants that could impact performance.

In addition, our specialized coatings solutions deliver enhanced protection against wear, corrosion, and moisture, essential for the delicate electronics used in hearing aids. These chemical coatings safeguard components, extending their lifespan and maintaining optimal sound quality.

With a focus on the unique needs of hearing aid technology, we provide a comprehensive suite of solutions that address the most demanding challenges of the medical industry. Through our soldering, cleaning and coatings products, we ensure hearing aids are built to last, perform efficiently, and provide users with consistent, high-quality sound.

Low & No Silver Alloys for Better Drop-Shock Resistance in Hearing Aid Devices

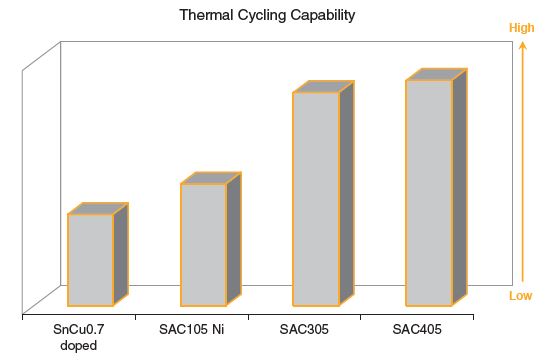

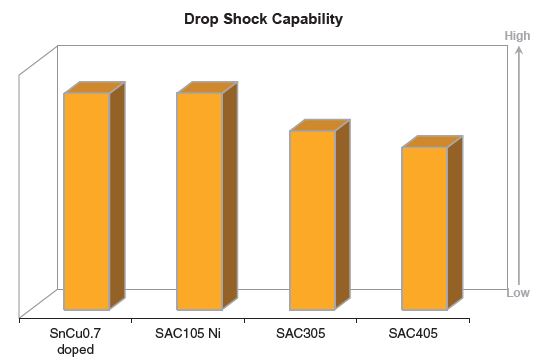

Electronic devices which are prone to be damaged by occasional drops are better off by using a solder alloy more resistant to drops. This is specially true for devices not exposed to high thermal stress like handheld devices, head phones, hearing aids, key fobs,…

The wetting behaviors of low-silver alloy SnAg1.0Cu0.5 are comparable to a considerable degree with eutectic standard SnAg3.0Cu0.5 and can be in many cases used as a “drop in” solution. The drop and vibration resistance of a low silver alloy compared to SAC305 could favor these alloys.

Discover our Low & No silver solutions

Contact an expert

PCB Protection Against Earwax and Skin Oil in Hearing Aid Devices

The mico-electronics from hearing aid devices or in-ear headphones could depending on the design, be exposed to earwax and skin oil.

This could lead to premature failure and can easily be avoided by applying an ultra-thin coating of less then a micro thick. A perfect solution for applications where limits of space and weight prevent other ways of protection.

Our Ultra-thin coatings are easy to apply by a dipping process and will due to it’s excellent surface tension flow into the smallest cavities. Coating and drying is done under 5 minutes.

Discover our Ultra-thin coating solutions

Contact an expert

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.