MEDICAL EQUIPMENT & SCANNERS

Soldering, cleaning & coating solutions for MRIscanners – measuring & drug delivery devices…

Select subsegment :

INVENTEC Medical Devices Solutions

INVENTEC specializes in providing advanced soldering, cleaning, coatings, and cooling solutions tailored for the medical sector, with a particular focus on medical equipment and scanners. Through innovative chemical products, we deliver high-performance soldering solutions that ensure durable, precise connections for critical medical devices.

Our cleaning solutions are designed to meet stringent industry standards, ensuring that medical equipment is free from contaminants, providing a safe and reliable performance for patients and healthcare professionals. The coatings we offer protect sensitive components, enhancing longevity and reducing wear and tear in medical scanners and diagnostic equipment, ensuring they remain operational over the long term.

Whether for soldering components, cleaning intricate parts, or applying protective coatings, our products provide comprehensive support for the medical industry. With a focus on medical equipment and scanners, we aim to deliver solutions that ensure both precision and reliability, helping healthcare providers deliver accurate diagnostics and improve patient outcomes.

Solder Solutions for Medical Devices

Medical devices has high reliability requirement because of it’s use as a life-saving tool. They are also relative expensive, so making sure they don’t stand idle or optimizing the life-time of the equipment, demands that the electronic assemblies are set up for the task. INVENTEC has several solder solutions with can greatly improve the reliability of the electronic used in medical devices.

Low void soldering solutions for better heat dissipation

Medical devices like MRI scanners, create quite some heat during operations. Although a cooling system is in place, making sure that the electronics are optimized to dissipate effectively the heat will extend the life-time of the device. Voids in the solder joint reduces the thermal dissipation and hence the reliability of the assembly. Using a paste especially developed to minimize the amount and size of voids under specific sensitive components is recommended and will improve the overall reliability.

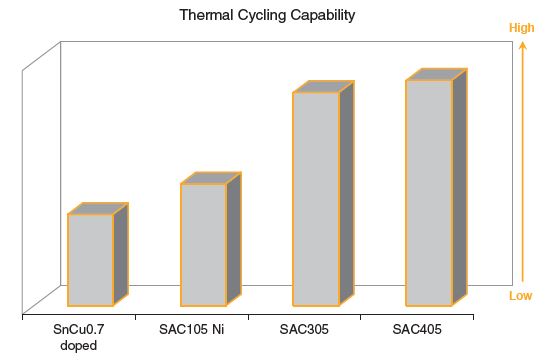

Alternative solder alloys for a better thermal cycling capabilities

Electronic assemblies which go daily through a thermal cycling process, exposing the electronics to substantial differences in temperature will put stress on the solder joints due to the expansion and contraction of the alloy. This will create over time cracks or worse breaks off the solder joint. By using an alloy that has better thermal cycling capabilities, you can enhance the lifetime of these medical devices.

Discover our low void solutions

Discover alternative alloys solutions

Contact an expert

PCB Defluxing to Enhance Medical Devices Reliability

The idea behind No-clean soldering is to avoid an additional cleaning step in your overall process. For certain critical applications however, there is no room for failure and removal of any contaminations left on the PCB is required. This is especially true for the automotive, Aerospace and Medical industry, where the expected life-time of the electronics are many years and where some electronic devices are critical for health & safety.

It is common knowledge that assemblies exposed to higher temperatures are more prone to electrochemical migration and leakage current. This makes cleaning of PCB’s exposed to this kind of environment a valuable choice. Also when applying a protective coating it is also advised to clean prior to the coating process in order to maximize the coating adhesion.

INVENTEC has developed a dedicated range of defluxing agents suited to you desired process. Designed to cater high volume assemblies with a fast and effective cleaning and with high regards to their environmental impact.

Discover our defluxing solutions

Contact an expert

PCB Coatings for Enhanced Medical Devices Reliability

In order to extend the life time of your electronic assembly and protect it against harsh environments they operate in, coating is a valuable option. Also they can provide additional mechanical strength to the assembly by absorbing vibrations.

INVENTEC offers several Conformal Coatings & Ultra-thin coatings. Ultra-thin coatings offers a more simple and cost advantage process, while traditional conformal coatings provide a more rigid protection. They both can be applied by selective spray or by dipping.

Although heat curing of conformal coatings is still very popular, we believe in the future of UV curing. Especially by using UV LED instead of the traditional mercury UV lamps, which is a more stable, cost-efficient and environmental processes.

When applying a protective coating it is also advised to clean prior to the coating process in order to maximize the coating adhesion. With INVENTEC you have a partner which can offer you soldering, cleaning and coating solutions. Designed to be compatible with each other to minimize the risk of compatibility issues.

Discover our coating solutions

Contact an expert

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.