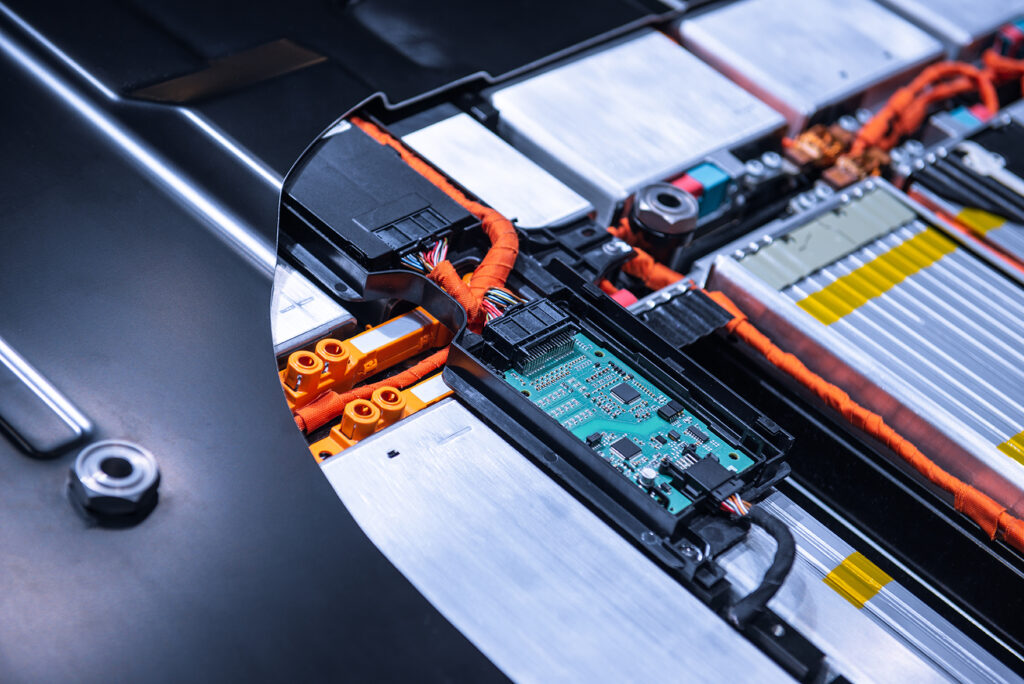

Battery Pack & Charge Port

Battery pack – Battery Management system (BMS) – Charge port

Select subsegment :

INVENTEC Charging Systems Solutions

INVENTEC specializes in providing advanced soldering, cleaning, coatings, and cooling solutions tailored specifically for the automotive sector, with a strong emphasis on charging systems applications. Our soldering solutions ensure reliable electrical connections, while our cleaning products are formulated to remove contaminants that could compromise performance and longevity.

With our coatings solutions, we provide added protection against wear and corrosion, ensuring the safety and efficiency of critical components like battery packs and charge ports in electric vehicles.

Whether it’s the need for soldering materials that withstand extreme conditions, precision cleaning agents for sensitive electrical parts, or specialized coatings for durability, our solutions are at the forefront of the automotive industry’s transition toward sustainable, high-efficiency vehicles.

By offering solutions for battery pack protection, charge port optimization, and thermal regulation, we help manufacturers achieve the highest standards in safety and performance.

Low Void Solder Paste for Better Heat Dissipation in Charging Systems

Fast EV charging stations work on high power output. The more higher the power output the more heat will be generated in the electronic / electric circuit. The same counts for the charge port and battery management system which has to be matched with the charging power.

Voids in the solder joint reduces the thermal dissipation and hence the reliability of the assembly. Using a paste especially developed to minimize the amount and size of voids under specific sensitive components is recommended and will improve the overall reliability.

INVENTEC has several combinations of alloy with Low Void chemistry available to cater your needs.

Discover our low void solutions

Contact an expert

PCB Defluxing to Enhance Charging Systems Reliability

The idea behind No-clean soldering is to avoid an additional cleaning step in your overall process. For certain critical applications however, there is no room for failure and removal of any contaminations left on the PCB is required. This is especially true for the automotive, Aerospace and Medical industry, where the expected life-time of the electronics are many years and where some electronic devices are critical for health & safety.

It is common knowledge that assemblies exposed to higher temperatures are more prone to electrochemical migration and leakage current. This makes cleaning of PCB’s exposed to this kind of environment a valuable choice. Also when applying a protective coating it is also advised to clean prior to the coating process in order to maximize the coating adhesion.

INVENTEC has developed a dedicated range of defluxing agents suited to you desired process. Designed to cater high volume assemblies with a fast and effective cleaning and with high regards to their environmental impact.

Discover our defluxing solutions

Contact an expert

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

Do you need cleaning or coating after soldering? We provide FREE-OF-CHARGE cleaning or coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. It is also possible to attend trials in person.