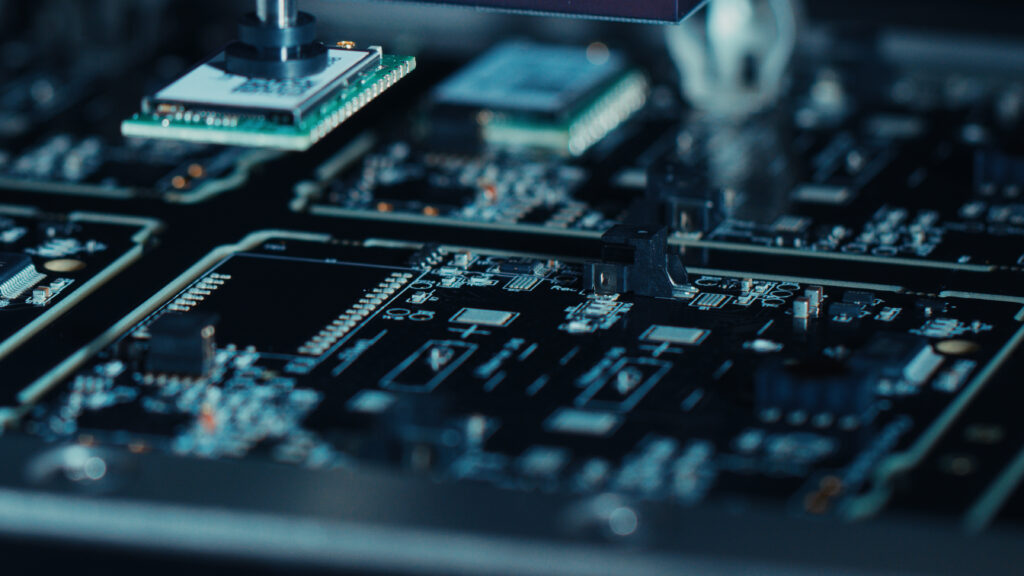

Nano Coatings & Ultra-thin Coatings

Hydrophobic & oleophobic coatings to protect electronics or other substrate with an easy, fast & environmental friendly process.

A fast, easy to apply & sustainable coating alternative

Nano Coatings & Ultra-Thin Coatings

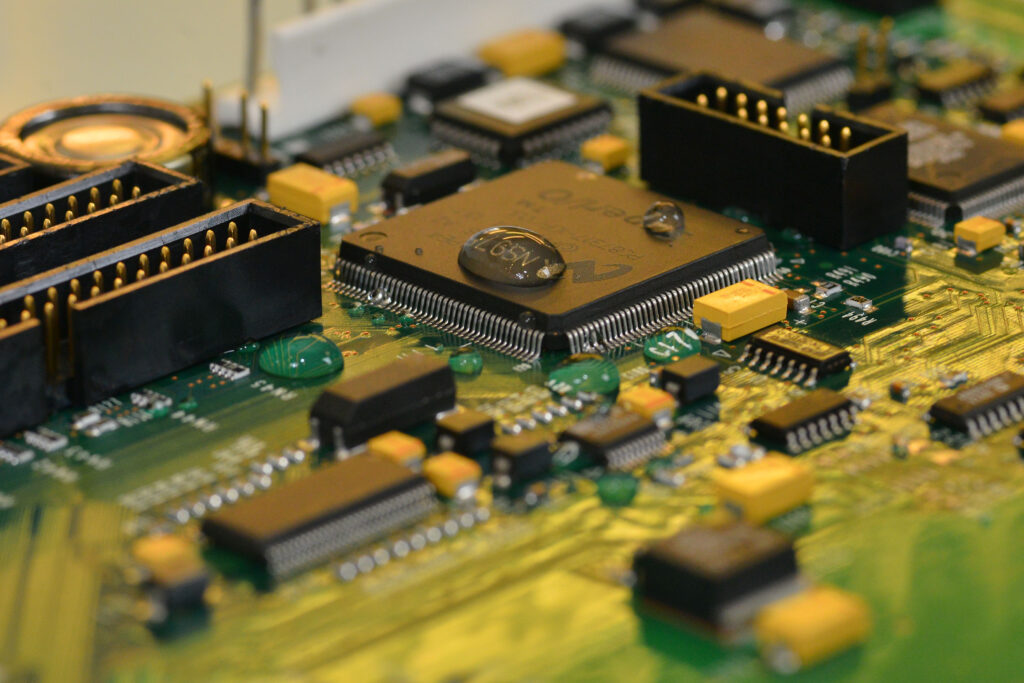

Nano coatings and ultra-thin coatings both offer advanced protection, but with some key differences. Nano coatings, created using nanotechnology, form a protective layer at the nanoscale, typically thinner than 1 micrometer, providing exceptional resistance against moisture, water, oil, dust, solvents, and chemicals. These nano coatings repel contaminants and maintain the surface’s integrity without adding bulk. While ultra-thin coatings are often considered a type of nano coating, not all ultra-thin coatings are produced using nanotechnology.

Ultra-thin coatings, though similar in thickness to nano coatings, don’t always involve the same nanoscale processes. Nevertheless, ultra-thin coatings provide excellent protection, preventing unwanted elements from affecting surfaces without altering their appearance. Both nano coatings and ultra-thin coatings can be applied by dipping, spray, or selective spray systems, ensuring comprehensive coverage and durability. While nano coatings leverage the unique properties of nanotechnology, ultra-thin coatings offer similar surface protection, making both types ideal for a variety of sensitive applications.

Advantages of using ultra-thin coatings

- Fast & easy process as it can be applied by dipping and dried at room temperature in a few seconds

- Non-flammable

- Very sustainable as low toxicity, low GWP, no ozon depleting.

- Masking can be in most application reduced or even avoided

- Space and weight saving

- Cost efficient solution as only little product is used to protect a certain surface

- Limited investment needs, even for low volume production quantities

- No impact on transmittion of Radio Frequencies (RF)

- No loss of light emissions or color changes when coating LED’s

The Ultimate Nano and Ultra-Thin Coating Solution

Besides, PROMOSOLV COAT UT10 is one of the most advanced nano coatings on the market. This ultra-thin coating delivers unmatched flexibility, providing exceptional protection with a minimal layer. Its superior adhesion and durability make it perfect for a wide range of applications, ensuring a high-performance finish every time. Upgrade your projects with the cutting-edge benefits of PROMOSOLV COAT UT10—where innovation meets reliability in a nano and ultra-thin solution.

PRODUCT OVERVIEW

We only show below the most relevant and newest products in our range. If you don’t find a specific product, you will probably find it with our search option.

Read moreShowing all 4 results

-

PROMOSOLV COAT UT10

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 1700 replacement

-

PROMOSOLV COAT UT10-UV

- Ultra-thin hydrophobic & oleophobic coating with UV tracer

- Dipping & spray process

- Easy & fast process

- Available in different dilutions

- 3M Novec 2704 replacement

-

3M NOVEC 1700

- Ultra-thin hydrophobic & oleophobic coating

- Dipping & spray process

- Easy & fast process

Alternative: PROMOSOLV COAT UT10

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

3M NOVEC 2704

- Ultra-thin hydrophobic & oleophobic coating with UV tracer

- Dipping & spray process

- Easy & fast process

Alternative: PROMOSOLV COAT UT10-UV

Technical support

Inventec has a worldwide dedicated Technical Support team to help you along the different stages of our cooperation.

Depending on your request, we provide online or onsite support

- to select the right product based on your specific needs

- to assist you in your product qualification process

- to guide you with the initial set up of you process at all your worldwide manufacturing facilities

- to provide fast response on technical issues which could occur at any time during mass production.

Free-of-Charge cleaning & coating trials

In order to know if our products reach your expectations on your specific part and according to your desired process, we provide FREE-OF-CHARGE cleaning and coating trials in our Technical Centers. A comprehensive technical report detailing all test results and recommendations regarding process & process parameters will be provided. You want to attend the trials? We are happy to welcome you.