TOPKLEAN EL 20P

High perfoming solder flux residues cleaner

- Removal of flux residues

- Co-solvent process

- Very high cleaning power & sustainable solution

TOPKLEAN EL 20P

Is especially designed to clean solder flux residues after reflow. It’s an upscaled formulation of TOPKLEAN EL 20A with improved sustainability and a reduction of surface tension to allow better cleaning under very low stand-off components. Its excellent ability to solubilize organic and minerals compounds allows to remove almost any solder flux residues used in the electronic industry today. It leaves no white residues and also provides a shiny effect on alloys & metals.

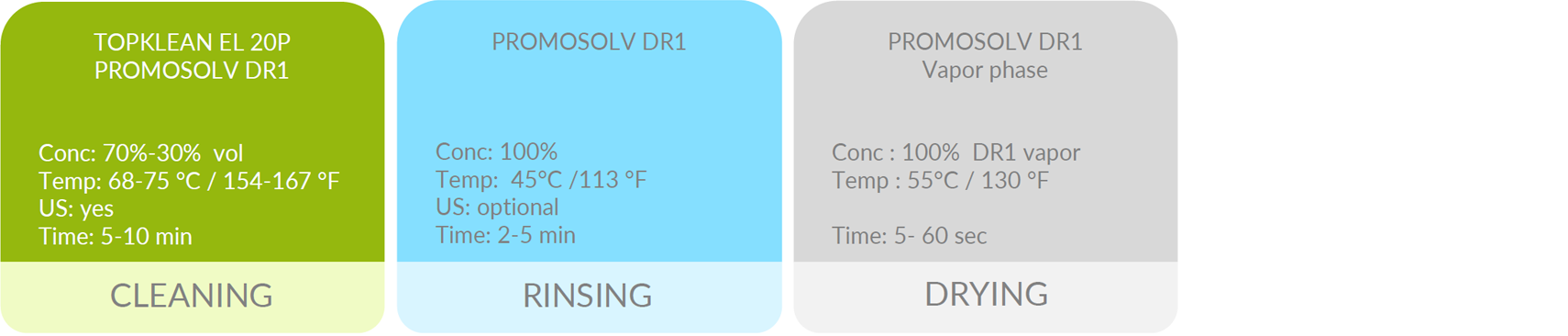

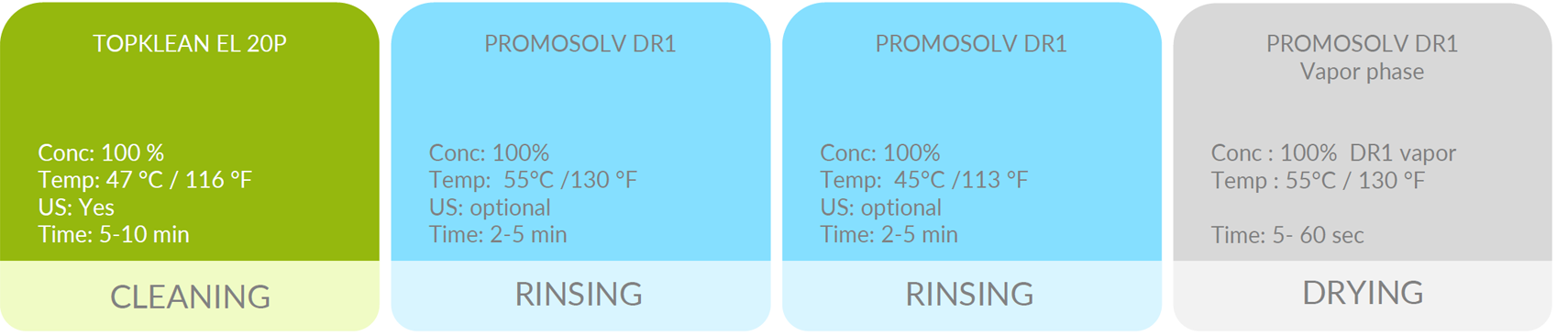

It is used in co-solvent process to offer a fast & sustainable cleaning process with very high cleaning efficiency. In this process, TOPKLEAN EL 20P is rinsed perfectly with Hydrofluoroethers (HFE) based rinsing fluids from 3M™ Novec or our own PROMOSOLV™ range. Thanks to the very low surface tension of HFE, the rinsing penetrate into the very tight spaces and under low stand-off components. It will dissolve any remaining flux residues, resulting in very low ionic contamination levels. Besides, compared with a water-based cleaning system, there is no risk of corrosion due to the absence of residual water left on the boards.

The co-solvent process has been a game changer for over 15 years now and is qualified and used by several actors in the electronic industry.

This is a product

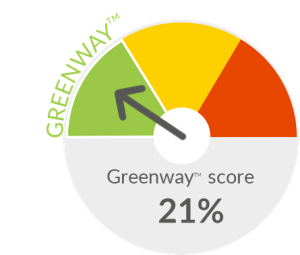

MAIN CONTRIBUTORS WHICH REDUCE IMPACT:

HUMAN HEALTH & SAFETY

- Non-toxic

- Low corrosive impact

- Non-flammable & high flashpoint

ENVIRONMENT PROTECTION & RESOURCES SAVINGS

- Low environmental impact: no H labelling regarding environment

- No GWP

- Non-corrosive for equipment

Benefits

Performance

- Excellent solubility organic & mineral residues

- Very low surface tension to allow excellent cleaning under low stand-off components.

- Excellent compatibility with materials used on PCB’s

- Allows shining effect to sensitive alloys & soldered surfaces

- leaves no white residues

- Waterless process – reduces risk of corrosion

Cost

- Fast process allows increase in production capacity

- Rinsing fluid is constantly recycled, limiting consumption.

- No water consumption & no need for wastewater treatment

HSE

- Low toxicity & non-corrosive product (refer to the SDS)

- No Ozon Depletion Potential (ODP) & no Global Warming Potential (GWP)

- High flash point – safe to use, storage & transport

- No aromatics & halogenated compounds