PROMOSOLV NEO B2

Sustainable cleaner

- Removal of wide range of contaminants

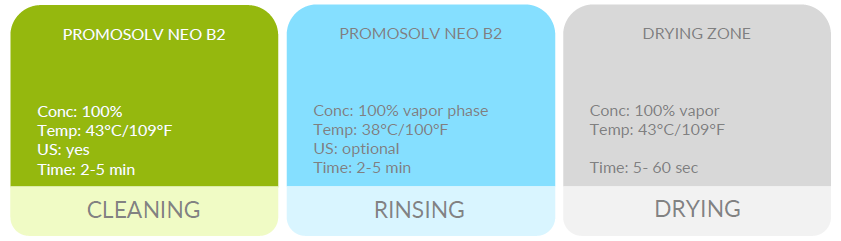

- Vapor phase (mono-solvent) process

- High cleaning power & ultra-low GWP

- 3M Novec 73DE replacement

PROMOSOLV NEO B2

Developed as a drop-in replacement for trichlorethylene, NPB and other solvents with a high Health, Safety & Environmental impact. While reducing substantially the HSE impact, the degreasing power is at an equivalent level. The very low surface tension allows to penetrate very tight or difficult to access spaces, providing a deep cleaning and rinsing.

The newly developed PROMOSOLV NEO range represents our products with an Ultra-low to No GWP & low atmospheric lifetime, in order to reduce global warming impact. The solvency power has also been improved, which contributes to an even better & faster cleaning performance.

PROMOSOLV NEO B2 It is dedicated to remove most kind of oils and greases, with the exception of water-based lubricants. Furthermore it is suitable for removing waxes and particles. Depending on the nature of polymerized materials, some varnishes, adhesives, inks & paints could also be removed.

PROMOSOLV NEO B2 is a drop-in replacement for 3M Novec 73DE which is scheduled to be phased out voluntarily by end 2025. Click on the link for more info on the announcement of 3M Novec phase out.

This is NOT a product

Although fully in line with safety & environmental regulations, this product doesn`t match our strict criteria to be labelled as a Greenway product.

LOOKING FOR A MORE SUSTAINABLE SOLUTION?

GREENWAY ALTERNATIVE

Discover more about Greenway

Benefits

PERFORMANCE

- Thermally and chemically stable in use

- The very low surface tension allows deep cleaning & rinsing of parts with complex geometry

- Short cleaning, rinsing and drying times

COST

- Continuous recycling in equipment for a long bath-life

- Can be returned for recycling and re-use

- The relatively high boiling point reduces risk of solvent drag, so limiting consumption

HSE

- Very low toxicity

- Ultra-low Global Warming Potential (GWP): 29

- No Ozon depletion potential (ODP)

- Non-flammable & azeotropic-like formulation